Description of the Shelf Panel Roll Forming Machine

Our shelf panel roll forming machine is a fully automated production line engineered for continuous, high-volume manufacturing. The process initiates with a decoiler that feeds a large steel coil—pre-painted or galvanized—into the system. The material undergoes precise leveling before being progressively conveyed through a series of forming stations.

Each station incorporates precision-engineered rollers that incrementally shape the steel strip into the desired cross-sectional profile of a shelf panel. The production sequence concludes with a flying cut-off mechanism, which trims the continuously formed profile to predetermined lengths without interrupting the operation, thereby ensuring optimal efficiency and consistent product quality.

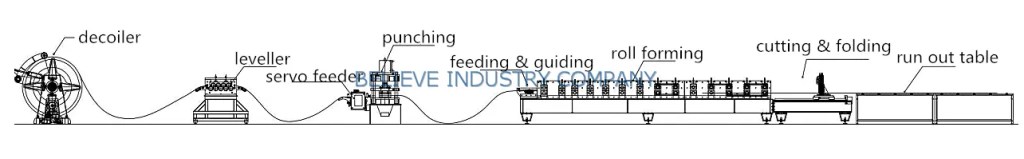

Key Machine Components and Machine Layout

Machine Components: decoiler — levelling unit – servo feeder — punching unit– feeding and guiding unit– roll forming unit – cutting and bending unit — collecting tables

Brief Specification Parameters

1. | Applicable Material | cold rolled steel coils, galvanized steel coils |

2. | Material thickness | 0.6-1.2mm |

3. | Decoiler | 5T hydraulic decoiler |

4. | Levelling unit | 7 roller leveller, top 3 rollers & bottom 4 rollers |

5. | Material of levelling rollers | 40Cr, Chromed |

6. | Levelling power | 5.5KW |

7. | Punching power | 11KW |

8. | Material of punching molds | Cr12, HRC58-62 |

9. | Power for servo feeder | 3KW |

10. | Roll forming steps | 14 steps |

11. | Material of rollers | GCr15, HRC58-62, Chromed |

12. | Material of shafts | 40Cr solid shafts, 70mm in diameter, chromed |

13. | Power for roll forming | 11kw |

14. | Transmission | electric chain transmission |

15. | Machine speed | 0-10m/min |

16. | Cutting & bending | hydraulic powered cutting, then end bending |

17. | Power for cutting & bending | 11kw |

18. | Cutting length tolerance | +/-0.5mm |

Application of the Finished Product

The primary product of this machine is the shelf panel, a vital component for various storage systems. These panels are characterized by their specific profiles, which often include reinforced ribs for added strength and lipped edges for safety and integration with shelf beams.

Industrial Pallet Racking: Durable decking for storing heavy pallets in warehouses.

Commercial Shelving Units: Shelves for retail stores, archives, and stockrooms.

Slotted Angle Shelving: The main horizontal surface for versatile, bolt-free shelving systems.