How to customize a roll forming machine for specific metal gauges is the most frequent technical challenge faced by manufacturers transitioning from light-gauge residential roofing to heavy-duty structural purlins. At Beli RollForming, we understand that a machine designed for 0.3mm steel will suffer catastrophic shaft deflection if forced to process 1.5mm material. Precision customization is not just an option; it is a requirement for structural integrity.

Before adjusting your rollers, it is vital to ensure your power system is up to the task. We recommend checking our expert guide on how to compare different motor brands for your roll forming machine to ensure your drive system can handle the increased torque required for thicker gauges.

1. Calculate the Roll Gap Clearance

The primary step in how to customize a roll forming machine for specific metal gauges is setting the roll gap. The gap between the upper and lower rollers must typically be 100% to 105% of the material thickness. If the gap is too tight, you will “scuff” the paint or stretch the metal; if it is too loose, the profile will lose its crispness.

Learn More>> How to Adjust Roll Forming Machine Rollers: 11 Incredible Secrets for Perfect Bending

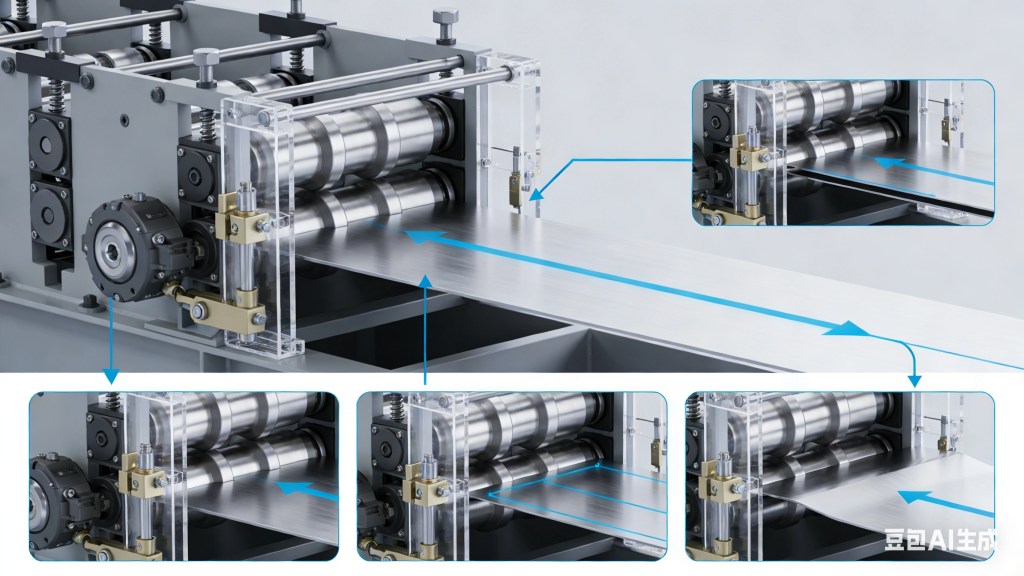

2. Shaft Diameter and Structural Rigidity

Thicker gauges exert massive upward pressure on the top shafts. When you customize for heavy gauges (e.g., 12-gauge or 14-gauge), the shaft diameter must be increased—often from 70mm to 90mm or more—to prevent “spring back” issues. This mechanical reinforcement is a cornerstone of Beli RollForming’s heavy-duty designs.

3. Selecting the Right Roller Material

How to customize a roll forming machine for specific metal gauges hinges first on selecting the optimal roller metallurgy—a critical decision that directly impacts equipment durability, product quality, and operational longevity.

For thin, prepainted metal coils, we specify chrome-plated GCr15 steel rollers as the ideal solution. This material combination eliminates surface scratches and preserves the integrity of pre-finished coatings, ensuring flawless end products. For heavy-gauge, hot-rolled steel processing, we deploy heat-treated Cr12MoV (D2) steel rollers, engineered to withstand extreme pressure and resist premature wear even under high-load continuous operation.

For applications requiring enhanced performance with ultra-high-strength or specialty metals, we also offer premium D2 or SKD11 steel roller configurations to meet the most demanding custom requirements.

4. Adjusting the Side-Rollers for Flare Control

Heavy-gauge metal has a high memory. To combat “end flare,” you must customize the side-roll stations. Adding adjustable side-rolls allows the operator to apply lateral pressure, “over-bending” the profile slightly so it snaps back into the perfect 90-degree angle required by industrial standards.

5. Tailoring the Feeding Guide System

The feeding guide is the first point of contact. If you are switching gauges, you must customize the entry width. At Beli RollForming, we provide manual hand-wheel or automatic motor-driven feeding guides that center the coil perfectly, ensuring the web of the profile remains consistent regardless of thickness.

6. Hydraulic Cut-off Force Calibration

A crucial part of how to customize a roll forming machine for specific metal gauges is the shearing system. Cutting 0.5mm steel requires significantly less hydraulic pressure than 3.0mm steel. Customizing your hydraulic station with a proportional valve allows for smooth cutting without “crushing” the ends of the finished profile.

7. Motor Torque and Gearbox Ratios

Thicker metal requires more “bite.” You may need to customize the gear ratio in your transmission. A higher reduction ratio provides the slow, steady torque needed to pull heavy gauges through multiple forming stations without stalling the motor or breaking the drive chain.

8. Leveling and Straightening Customization

Before the metal enters the first forming station, it must be flat. When learning how to customize a roll forming machine for specific metal gauges, pay attention to the de-coiler and leveler. Thicker gauges require a 7-roll or 9-roll leveler to remove “coil set” effectively.

9. PLC Software and Encoder Scaling

Finally, the brain of the machine must be updated. Customizing the PLC (Programmable Logic Controller) allows the operator to input specific material constants. Because thicker metal takes up more volume in the bends, the “developed width” of the coil changes. Your software must account for this to maintain length accuracy.

Engineering Standards for Steel

When customizing, always refer to the ASTM International standards for metal thickness tolerances. This ensures that your customized machine remains within legal safety limits for structural steel production. For European projects, ensure compliance with Eurocode 3 for cold-formed members.

Conclusion

Successfully customizing your machine is only the first step. If you are working with interchangeable profiles, you should also read our detailed walkthrough on how to calibrate a CZ Purlin roll forming machine to handle varying thicknesses in the same shift. Furthermore, once your gauges are set, you can explore how to optimize a double layer roll forming machine to produce two different thickness profiles on a single chassis.

Mastering how to customize a roll forming machine for specific metal gauges is what separates standard suppliers from engineering leaders like Beli RollForming. By focusing on roll gaps, shaft strength, and hydraulic force, you ensure your machine produces high-quality profiles for decades.

Need a Custom Gauge Solution? Contact Beli RollForming‘s technical department to discuss your specific thickness requirements. We provide turnkey solutions for gauges ranging from 0.2mm to 4.0mm.