Metal Floor Deck Roll Forming Machine is designed and manufactured for producing steel floor decking for steel buildings.

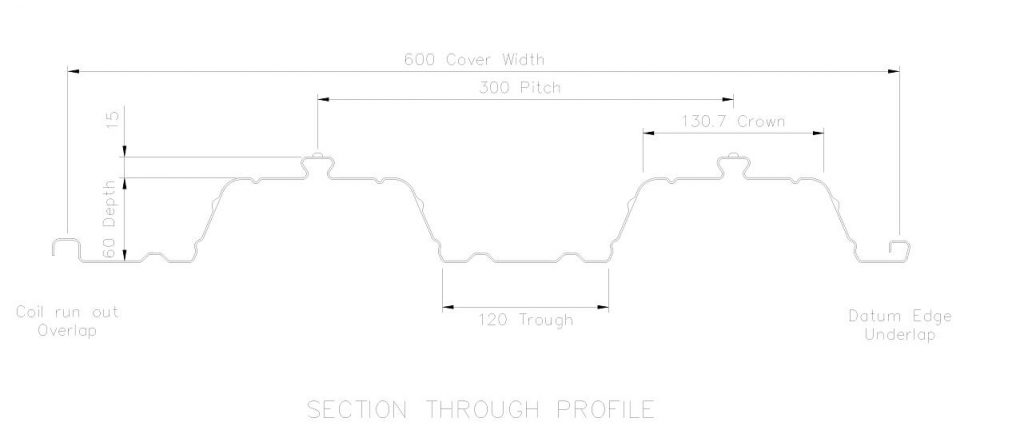

Profile Drawing

Material Details of Metal Floor Deck

Layout of Metal Floor Deck Roll Forming Machine

Technical Parameters of Metal Floor Deck Roll Forming Machine

Hydraulic Uncoiler with Coil Car

- Electric uncoiling, hydraulic loosen and tension

- Maximum capacity:11 Ton

- D:508mmO.D:1350mm

- Maximum width:1350mm,

- Hydraulic Power: 5.5KW, Uncoiling motor power:5.5KW

Roll Forming Machine

- Adopt H STEEL and Steel Plate Welded, side wall thickness: 25mm, 450mm H steel

- Rollers Station: 30, with several auxiliary rollers

- Diameter of Shaft: 100mm

- Material Of Shaft: 45# Steel With Heat Treatment HRC50~55

- Material Of Roller: GCR 15(ASRM a295:1998) Steel With Quenching Treatment and Chroming of 0.05mm Thickness

- Motor Power: 15KW*2

- Power Transition: by Gears&Chains( 2 inch single)

- Speed Control: by Frequency Inverter

- Speed of the machine: 10-15m/min

Hydraulic Cutting Device

- Material Of Cutting Mold: Cr12 Steel With Quenched Treatment HRC 60-62

- Cutting Length And Quantity: Clients Can Set The Length and Quantity on the PLC Touch Screen

- Hydraulic Station Power: 5KW

- Tolerance Of Cutting Length: +/-2mm

Control System

- The worker input the length and quantity of the product through touch screen, total 20 groups, the touch screen will show the working status of the machine,

- PLC Control Box: 700mmx1000mmx300mm

- Computer Control System: Mitsubishi PLC

- Frequency inverter: Mitsubishi

- Encoder: Omron Brand

- Limit switch: Omron

- Controlled System Power: Overload Protection

- Pressure Of Hydraulic Station: ≧12Mpa

- Current: 415 V Direct Current, 50Hz, 3 Phase

Collection Table

Collect the product after cutting, Angle Steel Welded, rollers chromed

Conclusion

The metal floor deck roll forming machine is an indispensable industrial solution for modern steel-framed construction. It delivers efficient, precise production of high-integrity floor deck profiles—compatible with galvanized steel, aluminum, and specialty materials—ensuring consistent dimensions and structural reliability. By streamlining prefabrication, it boosts on-site efficiency, supports composite concrete bonding, and adapts to diverse project needs (residential, industrial, commercial). A cost-effective, high-performance tool that underpins durable, fast-track building projects. Contact us today to customize your machine for specific deck profiles, capacity, and budget, and elevate your construction production efficiency.