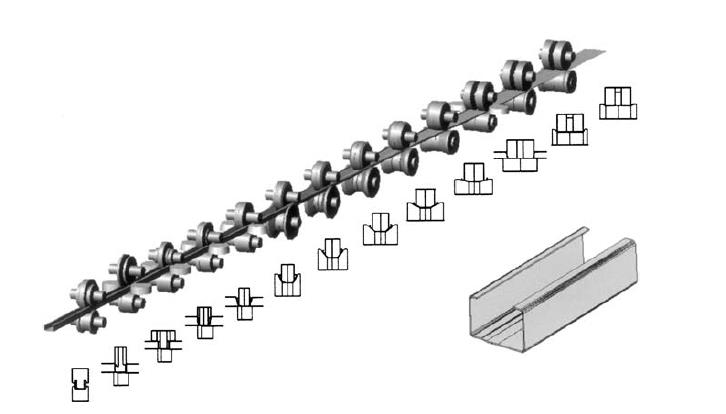

Cold roll forming is a continuous manufacturing process that converts flat strips of metal coil into complex profiles using a series of precisely synchronized roller dies. Unlike other metal forming techniques that rely on heat or immense pressure, this process achieves its final shape at room temperature, which is the source of its amazing advantages in modern industry.

At Beli RollForming, we understand that leveraging the secrets of cold roll forming is key to maximizing material properties, reducing waste, and achieving superior volume production. If you’re looking to invest in a new manufacturing solution, understanding these five secrets will highlight why a high-quality roll forming machine is the best asset for your factory.

The Core Principle of Cold Roll Forming

The “cold” aspect of the process ensures that the metal’s crystalline structure is refined through work hardening as it passes through successive roller stations. This mechanical deformation dramatically increases the yield strength and hardness of the finished profile compared to the original raw material. This principle is fundamental to why the final product is often stronger than its counterparts made via hot forming methods.

To learn more about how mechanical stress changes metal properties, we recommend checking out this external guide on the subject: Understanding Metal Work Hardening.

Unlocking the 5 Amazing Benefits of Cold Roll Forming

1. Superior Strength and Hardness

The most valuable secret of cold roll forming is the inherent material strengthening it provides. As the metal is bent and formed, the internal grain structure is permanently rearranged. This process, known as strain hardening or work hardening, means that the final profile possesses superior structural integrity, perfect for applications demanding high load-bearing capacity, such as structural building components or automotive frames.

2. Exceptional Material Utilization (Less Waste)

Because cold roll forming uses pre-slit coils and the forming process is highly precise, there is minimal material loss compared to stamping or machining processes that involve cutting away metal. This efficiency translates directly into lower material costs and a more sustainable, profitable operation. Modern Beli machines are designed to optimize every inch of the coil strip, drastically reducing scrap.

3. Unbeatable Production Speed and Volume

Due to its continuous nature, the process runs at remarkably high speeds—often faster than any batch-based manufacturing method. This is critical for meeting high-volume demands in construction and infrastructure projects. A single cold roll forming line can produce thousands of feet of complex profiles per day with minimal operator intervention once set up.

4. Maintaining Tight Dimensional Tolerances

The sequential nature of the roller dies allows for gradual, precise bending in controlled steps. This results in products with extremely tight dimensional tolerances and consistent cross-sectional accuracy along the entire length of the profile. This is crucial for components that need to fit perfectly into assemblies, like specialized window frames or interlocking panels.

5. Surface Finish Perfection

The smooth, hardened rollers impart a superior surface finish to the metal, eliminating the need for extensive post-treatment or grinding in many cases. The tight contact between the metal and the precision tooling minimizes surface defects, which is a major aesthetic and functional benefit, particularly for pre-painted or visible architectural products.

Conclusion

Mastering the use of cold roll forming technology gives manufacturers a decisive competitive edge in terms of quality, strength, speed, and cost efficiency. By focusing on precision tooling and advanced machine design, Beli RollForming helps unlock these five amazing secrets for your production line. We are committed to providing machines that leverage the full potential of cold forming metallurgy.

If you are ready to implement the superior quality and efficiency of cold roll forming in your operation, our experts are here to help.

Contact Beli RollForming Today for a Consultation:

Website: belirollforming.com

Email: enquiry@believeindustry.com

Phone/WhatsApp: +86-18616927760