Roll Forming Process can help you easy to know how the roll forming machine working before you buy a Roll Forming Machine. Believe Industry Company is engaged to design and manufacture Roll Forming Machines as per desired drawings, and the Roll Forming Process is based on the product.

Different Roll Forming Process

Roofing Sheet Roll Forming Process

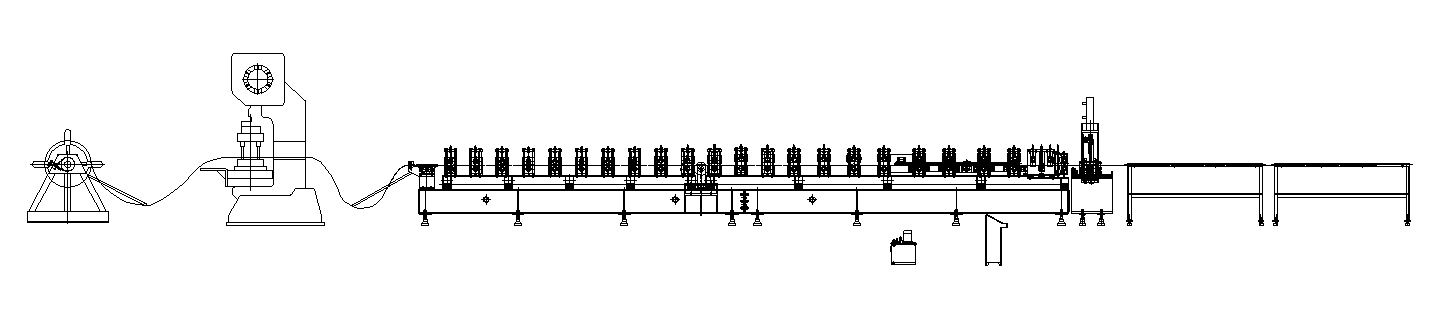

Roofing Sheet Roll Forming Machine Components are: Uncoiler, Roll Forming Machine, Cutoff Blade, Collection Table, Controlled Box and Hydraulic Station.

Believe IndustryRoofing Sheet Roll Forming Press is Uncoiling, Feeding and Guiding, Roll Forming, Cutting Off, Collection

Classic Metal Roof Tile Roll Forming Process

Metal Roof Tile Roll Forming Machine Components are: Uncoiler, Roll Forming Machine, Punch Steps Device Cutoff Blade, Collection Table, Controlled Box and Hydraulic Station.

Metal Roof Tile Roll Forming Process is Uncoiling, Roll Forming, Punching, Cutting off , Collecting

Online Punch Holes Roll Forming Machine Process

Online Punch Holes Roll Forming Machine, we have several designs. main divide into two kinds: Power Press Punch, Punch On the Machine

Power Press Punch

The line is include a separate power press for punching holes or notches.

The Power Press Roll Forming Machine Process is Uncoiling, Leveling, Punching, Servo Feeding, Roll Forming, Cutting Off, Collecting

Punch On The Machine

- Pre-Punch

The Process of Pre-Punch roll forming machine process is Uncoiling, Leveling, Punch, Roll Forming, Cutting and Collecting.

- Pre and Post Punch

The Pre and Post Punching roll forming machine process is Uncoiling, Leveling, Punching holes, Roll Forming, Punching Holes, Cutting, Collecting

Believe Industry Company also have more different roll forming process designs, all the designs are according to the design of the profiles. So how to design the machines and what will influence the processes?

- Material and thickness

- Holes measurements and position

- Speed of the line required

- Customized process is also accept

For more information, Contact us now!

Pingback: Material Influence Roll Forming Machine Design, Roll Former Design