Alamat

No 1, Jalan Yd, Daerah Huishan, Bandar Wuxi, Jiangsu. 214183

Waktu Kerja

Isnin hingga Jumaat: 9AM - 5PM

Sabtu: 9AM - 4PM

The cold proses membentuk gulungan is a sophisticated engineering method that transforms flat metal strips into precise, complex profiles through a series of continuous bending operations. For manufacturers and exporters like Beli RollForming, understanding this workflow is essential before investing in high-quality machinery.

Pada Beli RollForming (also known as Believe Industry Company), we specialize in designing and manufacturing customized roll forming machines based on your specific technical drawings. Because every profile is unique, the Sejuk proses membentuk gulungan must be tailored to the product’s geometry, material, and required output.

Every production line we build is engineered for durability and precision. While specific layouts vary, the fundamental roll forming machine process involves several critical stages to ensure the final product meets international standards.

The production of standard trapezoidal or corrugated roofing sheets requires a streamlined roll forming machine process. This line is designed for high-speed output and consistent quality.

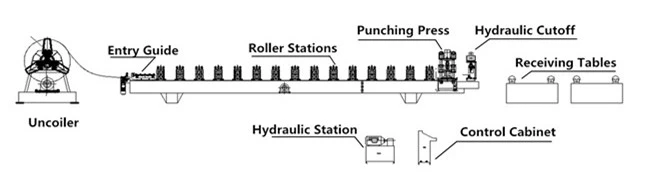

Standard Components:

Pembongkar: Holds and feeds the metal coil.

Roll Forming Machine: The heart of the system where rollers shape the metal.

Cut-off Blade: Precision hydraulic cutting.

Jadual Koleksi: Final product stacking.

Control Box & Hydraulic Station: The brain and power of the operation.

Classic metal roof tiles (glazed tiles) require an additional step to create the “step” effect that mimics traditional ceramic tiles.

Additional Components:

Punch Steps Device: A hydraulic press that creates the vertical “step” in the profile.

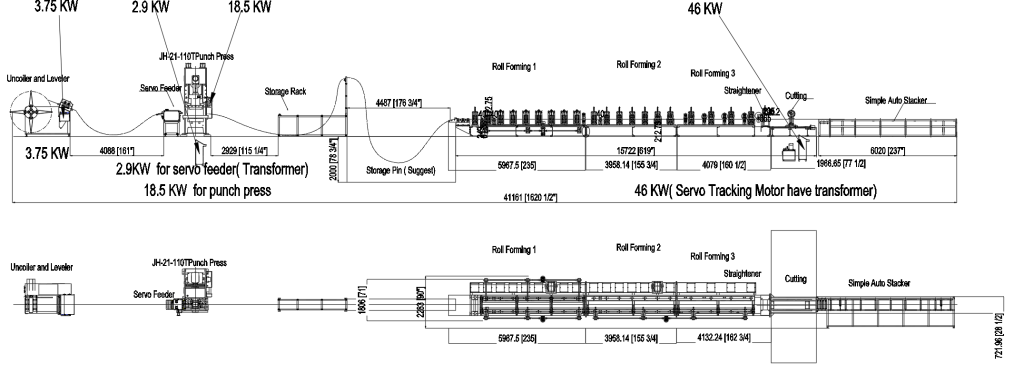

In modern manufacturing, many profiles require holes or notches for assembly. We offer several designs to integrate punching into the roll forming machine process.

This design includes a separate, high-speed power press located before the forming unit.

Pre-Punch: Holes are punched into the flat strip before it enters the rollers.

Pre and Post Punch: Ideal for complex profiles requiring holes on both the flat surface and the bent edges.

As a leading Chinese exporter, Beli RollForming designs the roll forming machine process based on several key variables:

Material Type and Thickness: Harder or thicker metals require more forming stations.

Hole Measurements and Position: Determines if you need a pre-punch or post-punch hydraulic system.

Line Speed Requirements: High-speed lines often require flying cutoff systems to maintain momentum.

Kerumitan Profil: Influences the number of roller passes required to reach the final shape.

Customization is our strength. Whether you need a simple C-channel machine or a complex multi-profile line, we ensure the roll forming machine process is optimized for your ROI.

For more information on how we can optimize your production, Contact Beli RollForming now!

Langgan sekarang untuk terus membaca dan mendapatkan akses kepada arkib penuh.