BELI® also have another roll forming mills, Duplex Mill. which is widely used in Steel Profile Roll Forming Machine. Steel Door Panel Roll Forming Machine, Panel Roll Forming Machine, Sandwich Panel production Line. Cable Tray Roll Forming Machine, C Purlin Roll Forming Machine, U Purlin Roll Forming Machine, C and Z Purlin Roll Forming Machine, etc.

What is Duplex Mill

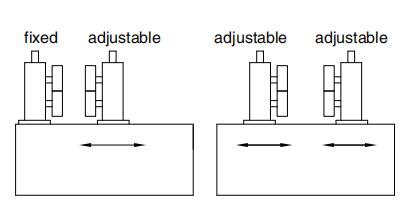

Two cantilevered mills facing each other are called

Advantage and Disadvantage of Duplex Mills

- Duplex mills have the same advantages and disadvantages as the cantilevered mills, except that the shaft end connecting pieces cannot be used. Some duplex mills have shafts extended at the other side of the mill, which can be used to form narrow sections.

- Duplex mills either have one side fixed and the other one adjustable, or both sides adjustable. Adjustment of a side is usually accomplished by placing all stands on one plate, which, with proper guides, can be moved in and out, thus changing the gap between the two cantilevered mills. And for duplex mills with one adjustable row of stands, the centerline of the product changes with width change.

- In the case of duplex mills with two adjustable rows of stands, the centerline of the products remains in the same position. This arrangement is used when holes are pre-punched at or around the centerline, either when the cutoff die has to be kept symmetrical or for other reasons when it is advantageous to keep the centerline in the same position.

How to adjust and use the Duplex Mill used in steel door panel roll forming machine

The width adjustment can be manual or motorized. The most sophisticated lines have PLC System to adjust the

Center support is used to avoid buckling of the wide flat center part. Because of the self-weight of the

material, the support is usually placed underneath the center part. However, if the horizontal vector of

the forces is large and the support prevents the sheet to buckle downwards, then it can buckle upwards.

To avoid upward buckling, additional support is placed on the top of the center part. When the width

is changed, the location (and possibly the number of the center supports) has to be changed too. Hence these

adjustments have to be taken into consideration at the design stage. It is also important that the support

should not scratch or mark the product. Embossing, lancing, louvering, or other similar operations, As usual, the door panel width is up to 1200mm or more, so our Steel Door Panel Roll Forming Machine adopt Center Support ” Fluent strip” , easy to adjust.