Address

No 1, Yd Road, Huishan District, Wuxi City, Jiangsu. 214183

Work Hours

Monday to Friday: 9AM - 5PM

Saturday: 9AM - 4PM

How to operate a double layer roll forming machine correctly is the difference between a high-profit production run and a pile of expensive scrap metal. At Beli RollForming, we specialize in dual-level engineering that saves floor space, but these machines require specific operational nuances. As we move into 2026, the demand for high-gloss, pre-painted finishes means that even a microscopic scratch can lead to a rejected order.

If you have already implemented our strategies on how to adjust roll forming machine rollers, you understand the importance of precision. However, operating a double-layer system introduces unique challenges regarding clearance and synchronization.

The primary risk when learning how to operate a double layer roll forming machine is the “shadow effect” or accidental contact between the idle level and the active level. Because two different profiles share the same frame and drive system, any vibration or misalignment can cause the material to scuff against the upper or lower components.

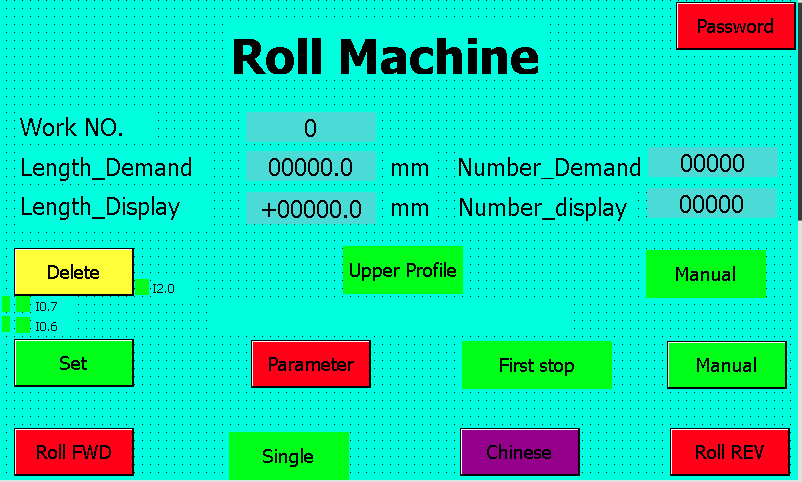

The first step in how to operate a double layer roll forming machine is mastering the control interface. Modern Beli machines use a specialized PLC toggle. Never attempt to feed material into both levels simultaneously. Ensure the clutch or motor drive is strictly engaged for only the level you are running to prevent “ghost rolling” of the idle shaft.

To prevent scratching, your rollers must be harder than the material but smoother than glass. We recommend rollers with a 0.05mm hard chrome plating. When learning how to operate a double layer roll forming machine, check these surfaces daily for “pick-up”—small bits of metal that weld themselves to the roller and cause repeating dents.

Material damage often starts before the first station. You must align the entry guide for the specific layer you are using. If the entry height is off by even 2mm, the strip will “shave” against the first set of rollers. This is a vital component of the critical guide to the 7 steps of the roll forming process.

Beli Rollforming’s newly designed pre-cutter features intelligent remaining length calculation: it accurately measures the leftover workpiece during production and cuts it off before the roll forming process is complete—significantly reducing material waste and lowering your production costs.

Double layer machines often use a double-stack cutter. A major secret in how to operate a double layer roll forming machine is ensuring the non-active blade is fully retracted. If the lower blade isn’t lowered enough while the top layer is running, the finished profile will catch on the blade as it exits, causing a “hook” or scratch on the tail end.

For high-end architectural panels, the most effective way to operate without damage is to apply a PE protective film. Integrate a film laminator at the entry point of your metal roof panel machine. The rollers will press against the film rather than the paint, ensuring a pristine finish.

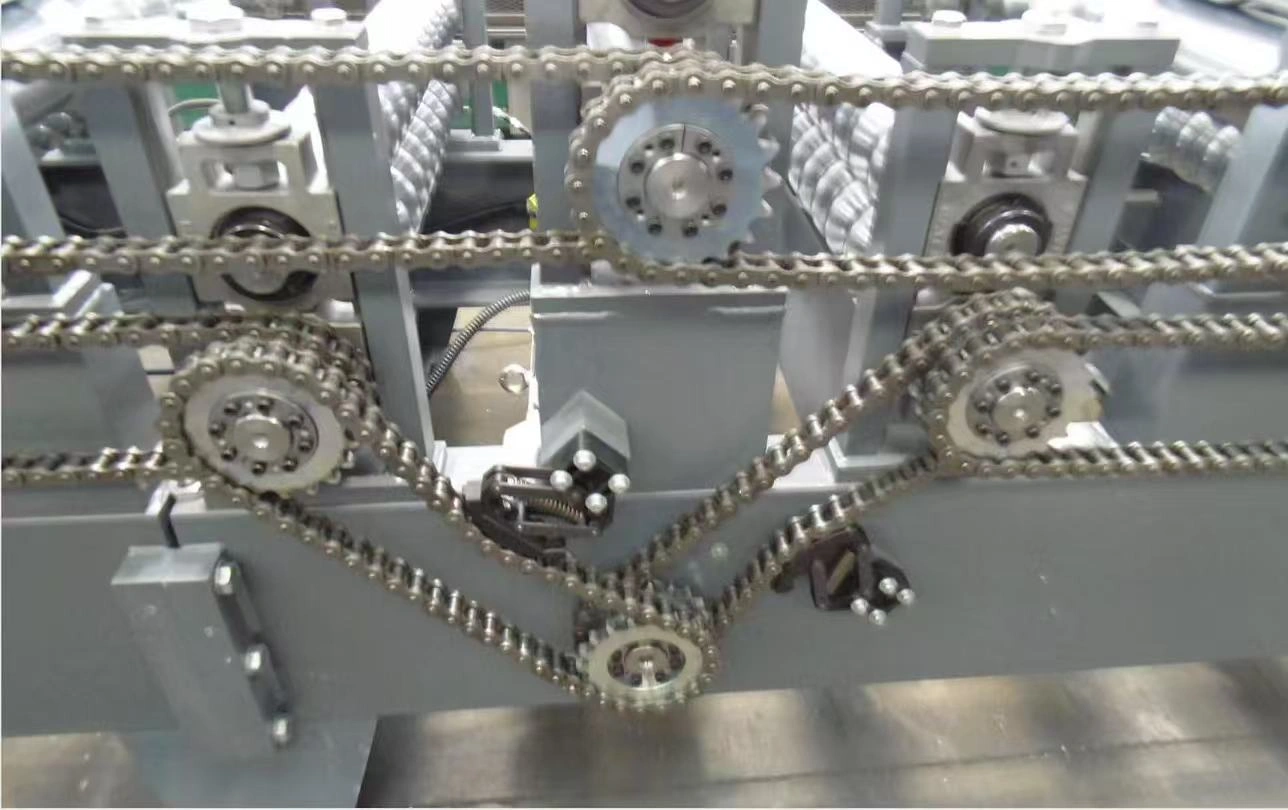

Vibration causes “chatter marks.” Because a double-layer machine has a taller profile, it is more susceptible to harmonic vibration. Check your drive chains regularly. If the chain is too loose, the rollers will “pulse,” creating visible horizontal lines on your material. This ties back into the roll forming alignment and calibration secrets.

When running the bottom layer, the top rollers are often physically close to the material path. Knowing how to operate a double layer roll forming machine involves verifying that the top level’s tooling isn’t so low that it creates a “pressure mark” on the lower profile. Always maintain at least a 10mm clearance between the idle tooling and the active strip.

Damage often occurs after the profile is formed. Ensure your exit receiving stacker is height-adjustable. If the exit rack is too low, the profile will drop and buckle; if too high, it will scrape the underside of the cutter frame. This is part of the roll forming advancement 2026 standards.

According to the American Iron and Steel Institute (AISI), surface integrity is a key metric for structural longevity. By following these 9 secrets, you ensure your production line meets global quality benchmarks, reducing waste and increasing your market competitiveness.

Understanding how to operate a double layer roll forming machine requires a “total system” approach. From the PLC settings to the exit rack height, every detail matters. At Beli RollForming, we design our machines to be user-friendly, but professional operation remains the key to longevity.

Ready to upgrade your production efficiency? Beli RollForming provides on-site training and high-precision dual-layer machines designed for the 2026 market. Contact our experts today to eliminate material damage from your workflow.

Subscribe now to keep reading and get access to the full archive.