Address

No 1, Yd Road, Huishan District, Wuxi City, Jiangsu. 214183

Work Hours

Monday to Friday: 9AM - 5PM

Saturday: 9AM - 4PM

The Storage Rack Horizontal Box Beam Roll Forming Machine is a cornerstone of modern industrial storage manufacturing. This highly specialized equipment is engineered for the continuous, high-volume production of critical horizontal beams used in pallet racking systems. At Beli RollForming, we have refined this machine to deliver exceptional precision, speed, and reliability, making it an essential asset for storage solution manufacturers seeking to maintain a competitive edge in the market.

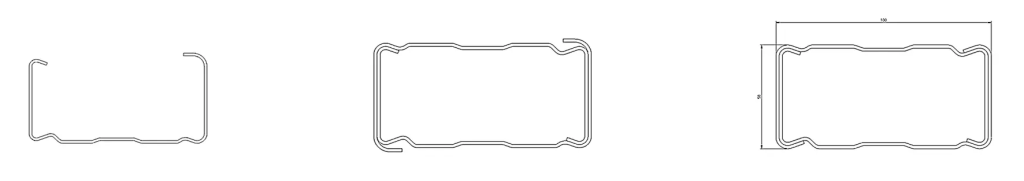

This Storage Rack Horizontal Box Beam Roll Forming Machine primarily consists of two components: a C-section beam roll forming machine and a box beam seaming machine. The C-section beam roll forming machine produces C-shaped profiles according to the customer’s specified dimensions and design drawings, while the seaming machine joins two separate C-sections to form a complete box beam.

The entire production process—from coil stock to finished box beam—involves several stages: coil unwinding (decoiling), feeding and guiding, leveling, roll forming, cutting, and seaming. C-section-based box beams are widely utilized in warehouse storage racking systems.

A Storage Rack Horizontal Box Beam Roll Forming Machine is designed to convert raw steel coils into durable, high-strength horizontal beams. These beams constitute the shelving levels of pallet racking systems, which serve as the structural backbone of warehouses, distribution centers, and logistics facilities worldwide.

Material Thickness | 1.0-2.0mm |

Box Beam Height | 40mm, 50mm |

Box Beam Width | 80mm, 90mm, 100mm, 110mm, 120mm |

Decoiler | Loading capacity | 5000kgs |

Power for decoiling | 3KW | |

Levelling Unit | Material of levelling rolls | 40Cr, 55mm in diameter |

Roll Forming Unit | Drive and transmission | Electric chain drive |

Forming steps | 18 steps | |

Forming speed | 0-15m/min | |

Roller material | GCr15, HRC58-62 | |

Shaft material | 40Cr; 80mm in diameter | |

Roll forming power | 15KW | |

Size adjustment power | 1.5KW | |

Servo Flying Cutoff | Servo tracking power | 2.2kw |

Cutting Power | 5.5KW | |

Cutting Blade Material | Cr12Mov | |

Seaming Machine | Seaming Steps | 5 steps |

Seaming Power | 11KW |

Additionally, we offer an alternative box beam machine designed for producing self-seamed (or self-locked) type box beams. Due to their advantages—such as reduced material consumption, higher production efficiency, lower overall costs, and reliable structural performance—the self-seamed box beam roll forming machines have attracted significant interest from customers.

| Weight | 8000-10000 kg |

|---|---|

| Dimensions | 20000 × 2500 × 1500 mm |