Address

No 1, Yd Road, Huishan District, Wuxi City, Jiangsu. 214183

Work Hours

Monday to Friday: 9AM - 5PM

Saturday: 9AM - 4PM

For manufacturers aiming for high volume, superior precision, and minimal material waste, the Roll Forming Process is the undisputed champion. However, maximizing the efficiency and quality of your line requires a thorough understanding of every stage, from the initial coil handling to the final stacking.

At Beli RollForming, we design and build machinery optimized for seamless execution of the entire sequence. Before diving into the specifics, it’s beneficial to review the foundational principles of metal forming. This critical guide will walk you through the 7 steps of the Roll Forming Process, ensuring you have the knowledge to master your production output. Understanding these steps is fundamental to leveraging the core advantages of roll forming technology.

The entire production cycle is a continuous, integrated chain. Each of the following seven stages is dependent on the flawless execution of the preceding one. Any interruption or error at an early stage can propagate throughout the entire line, underscoring the need for precision machinery and diligent oversight.

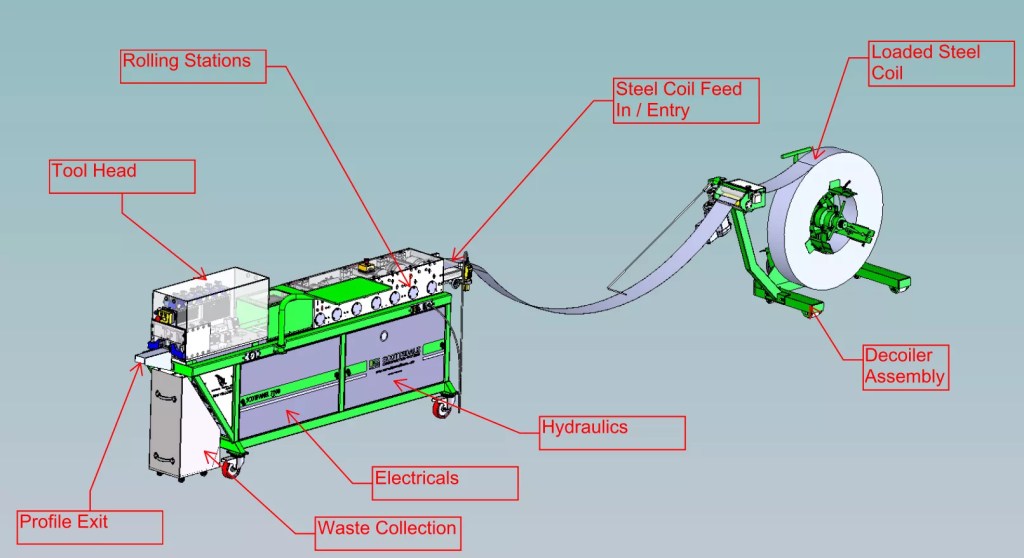

The Roll Forming Process begins long before the metal enters the machine. The first step involves selecting the correct coil and loading it onto the uncoiler or decoiler. This piece of equipment holds the heavy metal coil and allows the strip to feed into the line. The tension and speed must be precisely controlled here to prevent sudden jerks or slack, which could damage the strip or the subsequent equipment.

Once unwound, the metal strip passes through the entry guide and often a leveler or flattener. This is a crucial preparatory stage of the Roll Forming Process. The entry guide ensures the strip is perfectly centered before engaging the rollers. The leveler removes any residual curvature or camber from the coil, ensuring the material is perfectly flat and ready for the demanding work of forming. Without proper leveling, dimensional accuracy throughout the profile will be compromised.

This is the heart of the 7 Steps of the Roll Forming Process. The strip passes sequentially through a series of roll stands, each equipped with custom-designed roller dies. Each stand imparts a gradual change in the cross-section. Instead of making one sharp bend, the metal undergoes multiple small bends, minimizing stress and eliminating spring-back. The number of stations depends on the complexity of the final profile (simple profiles might use 8 stations; complex ones up to 30 or more).

For many applications, holes, slots, or notches need to be added to the profile. This step typically occurs either before the forming stations (pre-punching) for simpler profiles or after the forming stations (post-punching) for complex profiles. The mechanism must be synchronized precisely with the line speed to ensure every feature is placed accurately according to the profile length.

The fifth step involves cutting the continuous profile to the final specified length. High-speed flying shears or saws are commonly used. These cutters move at the same speed as the forming profile at the moment of the cut, ensuring a clean, precise, and square end without interrupting the continuous flow of the Roll Forming Process. This high-speed synchronization is a major engineering achievement in modern machinery.

After the profile is cut, it exits the machine onto an outfeed table or conveyor. This stage must handle the newly cut piece gently and quickly to prevent scratches, bending, or piling up, especially when producing long, lightweight, or easily damaged profiles. Automation here, such as automated grippers or magnetic conveyors, is key to maintaining quality.

The final of the 7 Steps of the Roll Forming Process is organizing the finished profiles for shipment or further processing. Automated stackers arrange the profiles into neat, counted bundles. Proper packaging ensures the profiles are protected from damage during transit to the job site or customer warehouse. High-quality packaging reflects the professionalism of the manufacturer.

Mastering the Roll Forming Process is about understanding the delicate balance between high speed and precision across these seven stages. At Beli RollForming, our machinery is engineered to ensure seamless integration and flawless execution of every step, enabling our customers to achieve unmatched output volume and dimensional consistency.

For continued learning about keeping your line running efficiently, we recommend reading our exist post: Unbeatable Advantages of Roll Forming machine: 3 Keys to Achieve Precision and Scale

If you are ready to implement the superior quality and efficiency of roll forming in your operation, our experts are here to help.

Contact Beli RollForming Today for a Consultation

Subscribe now to keep reading and get access to the full archive.