Address

No 1, Yd Road, Huishan District, Wuxi City, Jiangsu. 214183

Work Hours

Monday to Friday: 9AM - 5PM

Saturday: 9AM - 4PM

Think about the metal profiles around you right now: the sturdy roof above your head, the durable frame of your car, the shelves holding appliances, even the edges of your office furniture. Chances are, many were shaped not by brute force or complex machining, but by the elegant, continuous power of roll forming technology. This highly specialized and efficient manufacturing process is the backbone of countless industries, quietly revolutionizing how we produce long, complex metal shapes with unparalleled precision and speed.

At its core, roll forming is a continuous bending operation where a long strip or coil of metal (like steel, aluminum, copper, or alloys) passes through a meticulously designed series of rotating rolls mounted in consecutive stands. Each set of rolls incrementally bends the metal only a few degrees, gradually shaping it into the desired final cross-sectional profile without significantly changing the material’s thickness.

Imagine it like threading ribbon through a series of progressively tighter guides – each guide imparts a slight, specific bend. By the time the metal strip exits the final stand, it has been transformed into a consistent, complex shape – be it a simple C-channel, a complex multi-lobed tube, a customized roofing panel, or intricate window framing.

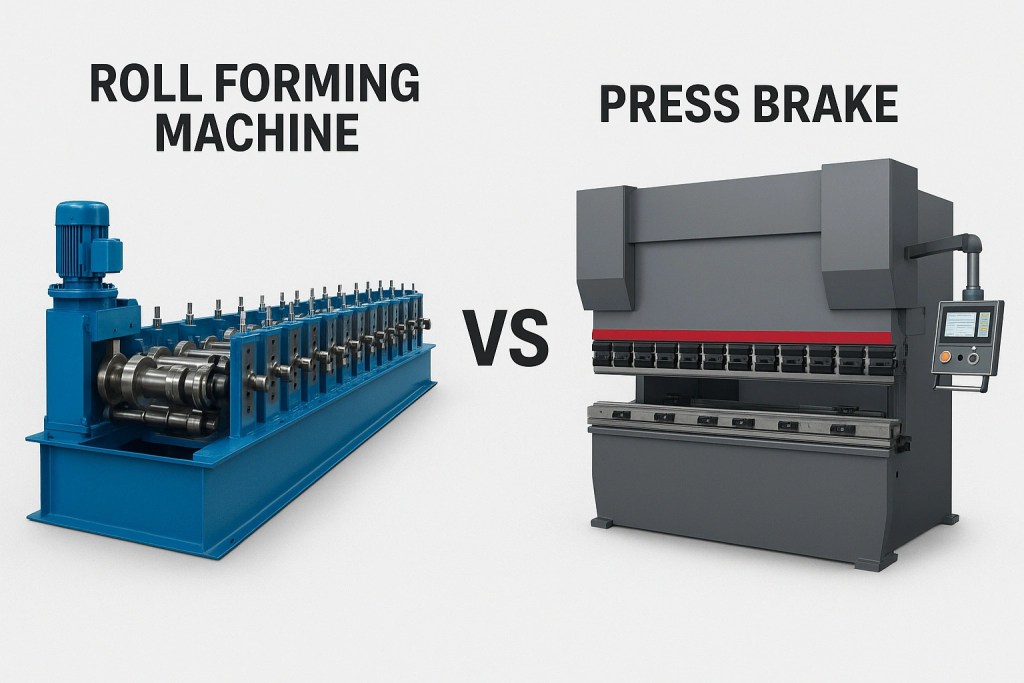

While press braking is excellent for short-run or highly varied parts, roll forming technology holds decisive advantages for long, continuous shapes in medium to high volumes:

| Feature | Roll Forming | Press Braking |

|---|---|---|

| Part Length | Excellent: Built for long, continuous parts. | Limited: Practical for shorter lengths only. |

| Production Speed | Superior: Hundreds of feet per minute. | Slower: Cycle time per bend. |

| Consistency | High: Near-identical parts continuously. | Variable: Operator skill dependent, piece-by-piece. |

| Complex Profiles | Excellent: Handles intricate multi-bend shapes. | Limited: Complexity increases time and cost. |

| Cost Efficiency | Best (High Volume): Low cost per part at scale. | Better (Low Volume): Lower tooling cost initially. |

| Setup Time | Longer Initially: Requires roll design/setup. | Shorter: Quicker tool changes for job shop. |

Learn More>>https://belirollforming.com/roll-forming-machine-vs-press-brake/

The applications are vast and essential:

Consider roll forming technology if your project involves:

The technology is constantly evolving. Trends include:

View More>>https://belirollforming.com/roll-forming-machine-trends-2025/

Roll forming technology is far more than just bending metal. It’s a sophisticated, high-precision manufacturing solution that delivers speed, consistency, cost-effectiveness, and the ability to create incredibly complex profiles vital for modern industry. From the skyscraper above you to the vehicle you drive, roll forming shapes the world in ways we often overlook.

If you’re involved in manufacturing long metal components or exploring alternatives to less efficient processes, investigating roll forming technology could be the key to unlocking significant competitive advantages in quality, speed, and cost. Partnering with an experienced roll forming manufacturer is the crucial first step to realizing its full potential for your products. Explore how this powerful technology can shape your future success. Learn more about roll forming machine

Subscribe now to keep reading and get access to the full archive.