Address

No 1, Yd Road, Huishan District, Wuxi City, Jiangsu. 214183

Work Hours

Monday to Friday: 9AM - 5PM

Saturday: 9AM - 4PM

Metal Tile Roof Panel Roll Forming Machines serve as the cornerstone of modern and efficient construction material manufacturing. At Beli RollForming, we engineer these advanced systems to convert raw steel coils into high-precision, aesthetically pleasing metal tile panels with exceptional consistency and speed.

A Metal Tile Roof Panel Roll Forming Machine is a fully automated production line designed to continuously shape metal coils into panels that replicate the appearance of traditional clay or concrete tiles. The cold-forming process preserves the material’s structural integrity, resulting in a lightweight yet highly durable final product.

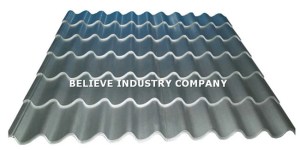

The primary output of this machine is the metal tile roof panel. These panels combine the classic and elegant appearance of traditional roofing tiles with the enhanced performance characteristics of modern steel.

Application: Residential Roofing, Commercial Buildings, Agricultural Structures

The advantages: these panels are lighter than traditional tiles, thereby reducing structural support requirements; they are fire-resistant, energy-efficient, and capable of withstanding harsh weather conditions.

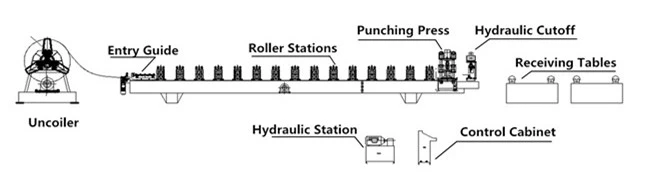

The tile effect roof panel machine shares a similar design configuration with standard roofing sheet forming machines. The complete production line consists of a hydraulic decoiler, a roll forming unit, a hydraulic cutting device, and a control system. However, the key distinction lies in an additional punching stage that occurs after roll forming but before cutting. This punching unit creates stepped features on the roofing sheet to achieve the desired tile-like appearance.

Working Process: uncoling — feeding and guiding — roll forming — punching — cutting — collecting

The table below presents the standard specifications of our machine. We specialize in customized solutions to meet your specific material and output requirements.

Metal Tile Roof Panel Roll Forming Machine | ||

1 | Applicable Material | Color-coated steel coils, galvanized steel coils |

2 | Material Thickness | 0.3-0.5mm |

3 | Material Width | 1219mm (profile-dependent) |

4 | Forming Speed | 15m/min |

5 | Line Speed | 3-5m/min |

6 | Number of Roller Stations | 18-24 stations |

7 | Shaft Material | 40Cr, diameter 75 mm, hardness HB 220–260 |

8 | Roller Material | No. 45 steel, quenched and tempered; surface-hardened with 0.05 mm chrome plating |

9 | Roll Forming Power | 7.5kW |

10 | Drive Method | Electric chain drive |

11 | Punching Die Material | Cr12MoV, hardness HRC 58–62 |

12 | Punching Power | 11kW |

13 | Cutting Blade Material | Cr12MoV, hardness HRC 58–62 |

14 | Cutting Power | 11kW(shared hydraulic station with punching unit) |

Investing in a high-performance Metal Tile Roof Panel Roll Forming Machine represents a strategic decision for any building materials manufacturer. It enables the efficient and profitable production of premium-quality roofing panels.

At Beli RollForming, we do not merely supply machinery; we deliver comprehensive production solutions supported by expert engineering, reliable after-sales service, and a strong commitment to your operational success. Our machines are engineered for durability, precision, and ease of operation.

Ready to enhance your production capabilities? Contact our technical team today to discuss your specific requirements and receive a customized quotation. Let us support you in building the future—one panel at a time.

| Weight | 8000-10000 kg |

|---|---|

| Dimensions | 15000 × 1800 × 1500 mm |