Address

No 1, Yd Road, Huishan District, Wuxi City, Jiangsu. 214183

Work Hours

Monday to Friday: 9AM - 5PM

Saturday: 9AM - 4PM

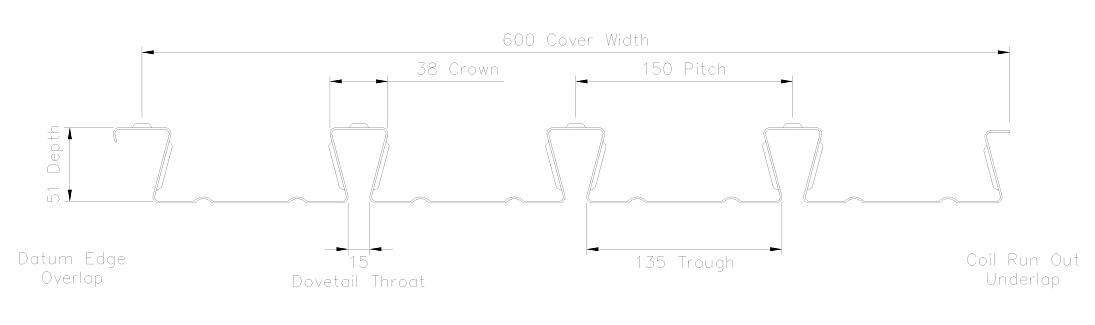

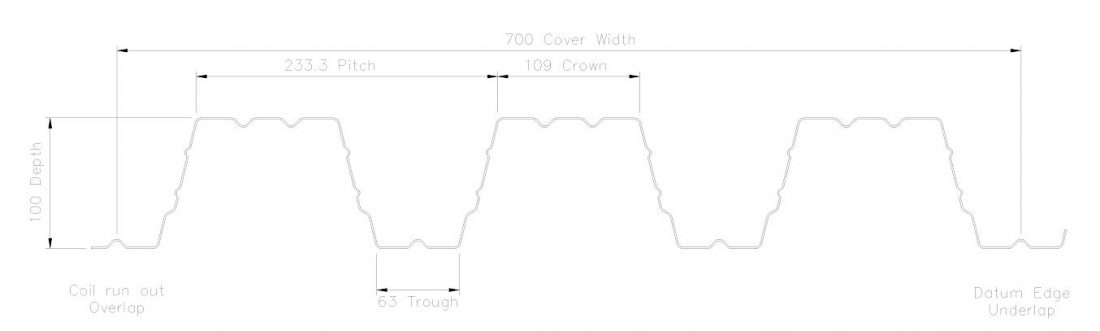

Steel Floor Deck Roll Forming Machine is designed and manufactured for producing steel floor decking for steel buildings.

Material Information:

Collect the product after cutting, Angle Steel Welded, rollers chromed

Believe Industry Company have series types of Steel Floor Deck roll forming machine, and we also accept customized profile. View more.

| Weight | 10000 kg |

|---|---|

| Dimensions | 16000 × 1500 × 1500 mm |