Address

No 1, Yd Road, Huishan District, Wuxi City, Jiangsu. 214183

Work Hours

Monday to Friday: 9AM - 5PM

Saturday: 9AM - 4PM

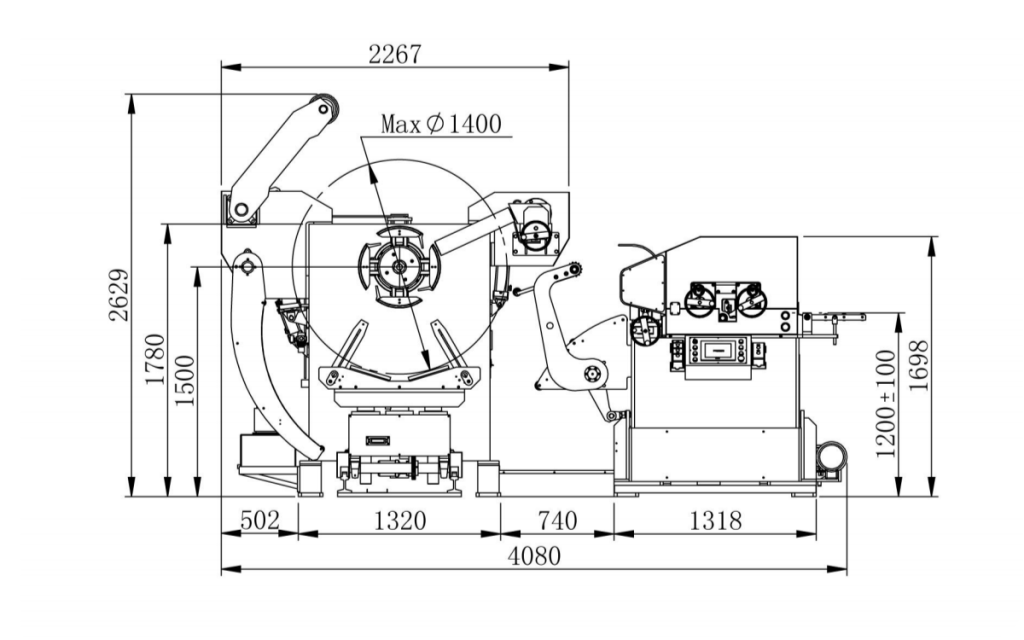

Uncoiler Straightener Feeder is an intergrated machine which widely used for punch industry. The machine is easy to feed the coil/material into the punch machine with small footprint, easy opration and other characteristics. And can be mounted with coil car for easy loading coil.

Believe Industry Company offering different types of uncoiler straightener feeder for different applications. Contact us now for more info. or Whatsapp directly.