Address

No 1, Yd Road, Huishan District, Wuxi City, Jiangsu. 214183

Work Hours

Monday to Friday: 9AM - 5PM

Saturday: 9AM - 4PM

Address

No 1, Yd Road, Huishan District, Wuxi City, Jiangsu. 214183

Work Hours

Monday to Friday: 9AM - 5PM

Saturday: 9AM - 4PM

For manufacturers aiming for high volume, superior precision, and minimal material waste, the Roll Forming Process is the undisputed champion. However, maximizing the efficiency and quality of your line requires a thorough understanding of every stage, from the initial coil…

In the competitive landscape of modern manufacturing, selecting the right fabrication process is critical. While stamping, bending, and extrusion each have their place, the continuous, high-volume capabilities of roll forming offer clear and unbeatable advantages of roll forming machine that…

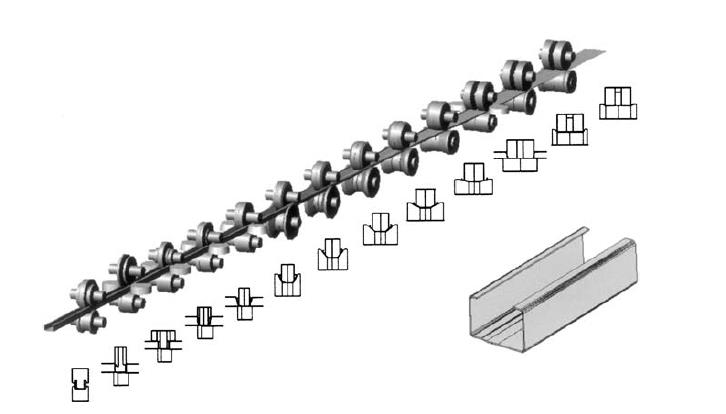

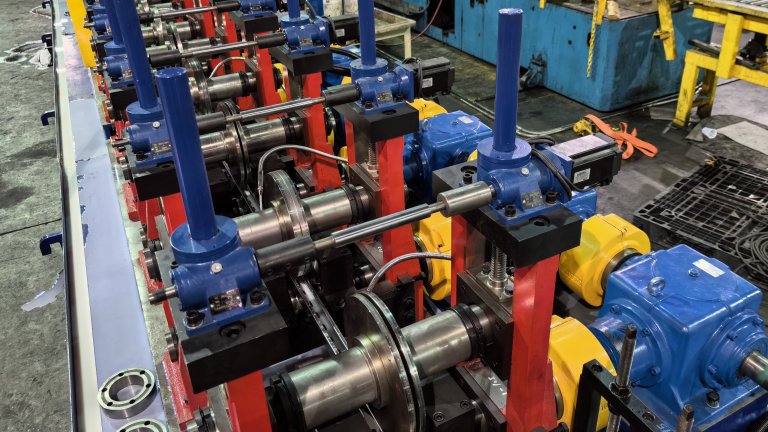

Cold roll forming is a continuous manufacturing process that converts flat strips of metal coil into complex profiles using a series of precisely synchronized roller dies. Unlike other metal forming techniques that rely on heat or immense pressure, this process…

Why Every Roofer Needs This Technology Roll forming machine for roofing systems are revolutionizing construction by transforming raw steel coils into weatherproof, architecturally precise panels in under 90 seconds. Contractors replacing manual methods report: Case Study: After installing Believe Industry’s…

Think about the metal profiles around you right now: the sturdy roof above your head, the durable frame of your car, the shelves holding appliances, even the edges of your office furniture. Chances are, many were shaped not by brute…

Industrial roll forming machines are transformative capital investments—driving efficiency for metal fabrication, construction, and automotive sectors. But with prices spanning 80,000 to over 800,000, manufacturers must dissect what truly impacts the bottom line. This guide demystifies 2024 pricing structures and…

China roll former has become indispensable for producing consistent, high-quality metal profiles in the dynamic world of manufacturing. Among global suppliers, China has emerged as a powerhouse, offering advanced, cost-effective solutions that cater to industries worldwide. What is a Roll…

Roll form pallet rack is one of solutions that consistently delivers on the warehousing and logistics, maximizing space, improving accessibility, and ensuring cost-effectiveness are top priorities. Designed to streamline storage operations, this versatile system is a staple in industries ranging…

Roll Forming machine lubrication systems. which are always overloocked while producing everything from strut channel, pallet racking, stainless products with precision and speed. Proper lubrication minimizes friction, reduces wear, and ensures consistent product quality. This article explores the critical role…

Advantages of Roll Forming Roll forming is a continuous metal fabrication process that shapes flat metal sheets or coils into precise cross-sectional profiles using a series of rollers. Unlike stamping or extrusion, roll forming is ideal for high-volume production of…