Address

No 1, Yd Road, Huishan District, Wuxi City, Jiangsu. 214183

Work Hours

Monday to Friday: 9AM - 5PM

Saturday: 9AM - 4PM

Address

No 1, Yd Road, Huishan District, Wuxi City, Jiangsu. 214183

Work Hours

Monday to Friday: 9AM - 5PM

Saturday: 9AM - 4PM

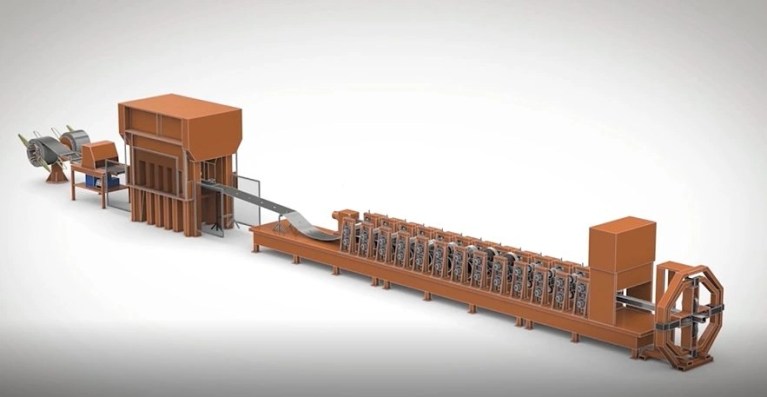

Roll Forming Machine, to forming steel coils/strips along straight, longitudinal, parallel bend lines with multiple pairs of contoured rollers without changing the thickness of the material at room temperature. Believe Industry Company have a full range of roll forming machines for Roofing Sheets, Wall Cladding, Steel Floor Decks, Studs and Tracks, purlins And also for Warehouse Storage System, Roller Shutter Door System, Garage Door System, etc.

Roll Forming machine is a flexible process, where both the dundamental rules and the exceptions can be utilized. It have been proben several times that even seemingly impossible roll forming tasks can be accomplished, although it may take a longer time and much more money. On the other hand, it has also been shown that plans to roll form simple shapes can create disastrous results if the basic rules of roll forming are not followed..

From our website, you will learn how to choose a suitable roll forming machine as well.

What is Electric Vehicle Battery Tray Roll Forming? Electric Vehicle Battery Tray Roll Forming is a specialized high-speed manufacturing process used to produce structural frames for EV batteries. By progressively bending Ultra-High-Strength Steel (UHSS) or aluminum through tandem roller sets,…

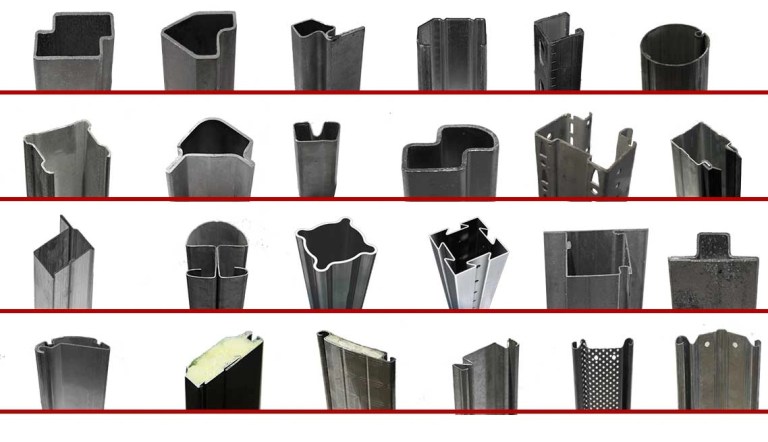

Custom roll formed profiles are complex, continuous metal shapes produced by feeding sheet or strip metal through a series of mated rollers. This process is ideal for long-length, high-volume production, allowing for intricate geometries, integrated punching, and tight tolerances that…

In the competitive landscape of industrial manufacturing, selecting the right metal-shaping process is the difference between a high-margin success and a logistical bottleneck. While both processes create long, consistent profiles, the engineering advantages of roll forming vs extrusion often tilt…

In the high-stakes world of industrial manufacturing, every second of idle time translates to lost revenue. For facilities handling diverse profiles—from rain gutters to complex structural channels—the ability to transition between products rapidly is no longer a luxury; it is…

Master roll forming machine speed optimization with expert tips on material handling, cooling, and tooling to maximize your industrial manufacturing output.

In the global steel construction industry, the C purlin roll former stands as a cornerstone of structural integrity. As building codes become more rigorous and material costs fluctuate, the demand for high-efficiency, zero-waste manufacturing has never been higher. At Believe…

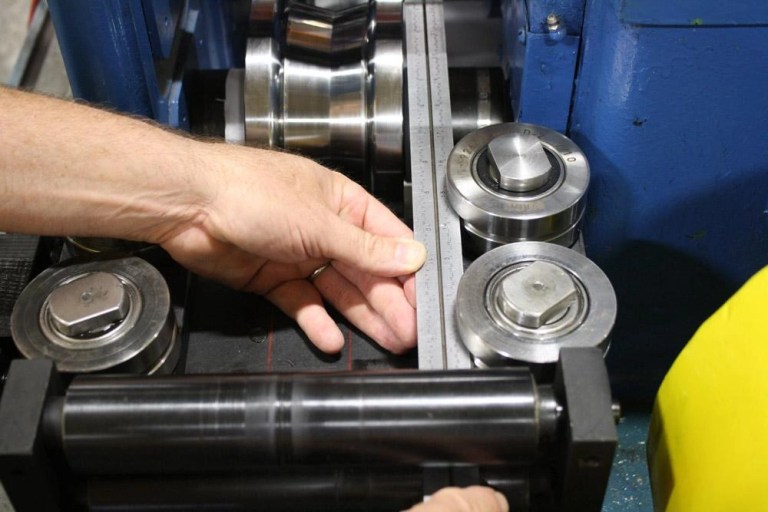

Roll Forming Alignment and Calibration is the invisible foundation of every successful manufacturing run. Even the most expensive roll forming tooling will fail if the machine’s horizontal and vertical planes are not perfectly synchronized. In the competitive landscape of 2026,…

A significant Roll Forming Advancement is currently reshaping how the world builds infrastructure, and as we enter the 2026 New Year, Beli RollForming is leading this technological charge. We don’t just see a new calendar year; we see a new…

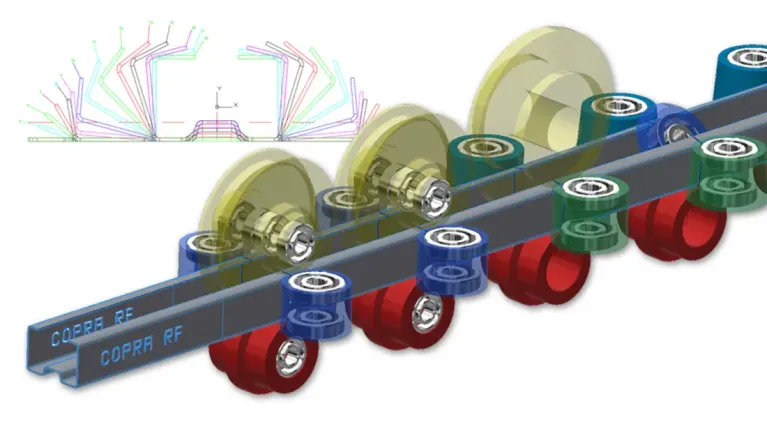

Learning how to set up a roll forming machine is the foundational skill that separates amateur workshops from world-class manufacturing facilities. In 2026, as Beli RollForming introduces 5 Incredible Advancements, including “Plug-and-Play” tooling and AutoCAD-integrated software, the technical setup remains…

The Metal Roll Forming Machine remains the heart of the global industrial sector as we move into 2026. For manufacturers and construction firms, the ability to produce consistent, high-strength profiles at a low cost per unit is no longer just…