Address

No 1, Yd Road, Huishan District, Wuxi City, Jiangsu. 214183

Work Hours

Monday to Friday: 9AM - 5PM

Saturday: 9AM - 4PM

Address

No 1, Yd Road, Huishan District, Wuxi City, Jiangsu. 214183

Work Hours

Monday to Friday: 9AM - 5PM

Saturday: 9AM - 4PM

Rolls design must match the roll forming mill. The roll designer must have all the relevant equipment dimensions and other data which can influence roll design. Otherwise the machine will be very costly. Types of Mills Influence Roll Design Cantilever…

Materials are selected to suit the specified product requirements at the possible lowest price. However, the mechanical properties, surface, deviation from thickness, width, straightness, and flatness of the raw material influence roll forming machine design. Mechanical Properties During roll forming…

Compared with bending and cutting machine. Roll Forming Machine Tolerance will be a bit big. But considering the speed of the machine, the end users will also prefer the roll forming machine.

Formed or Stretched Grooves Frequently, relatively shallow grooves are design to improve appearance, minimize center waviness or add strength to the product. The grooves can be either formed or stretched into the flat area. Where to form or sketch…

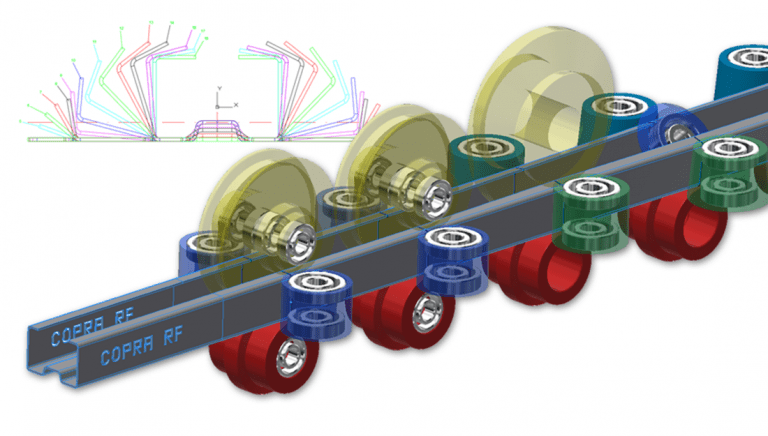

As we know that, During roll forming, a flat strip is gradually formed to the finished sections, The forming is almost exclusively accomplished groups of rollers while the material go through the roll forming mill. This article will be talking…