Address

No 1, Yd Road, Huishan District, Wuxi City, Jiangsu. 214183

Work Hours

Monday to Friday: 9AM - 5PM

Saturday: 9AM - 4PM

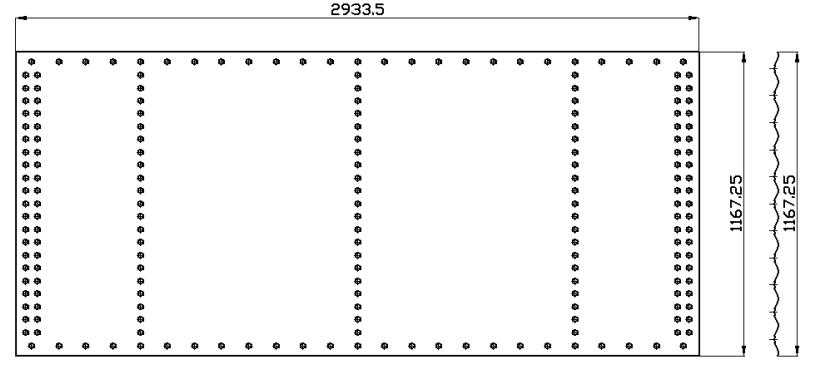

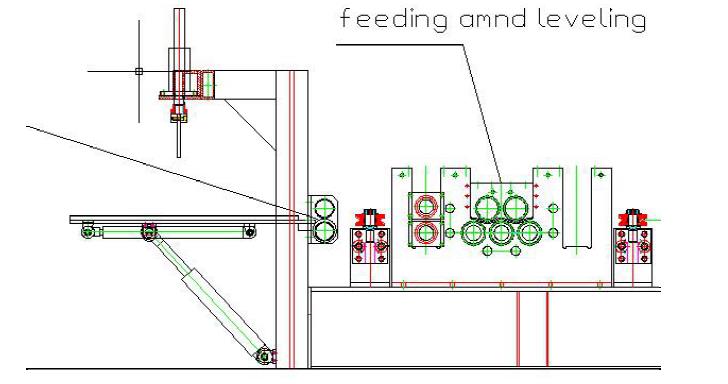

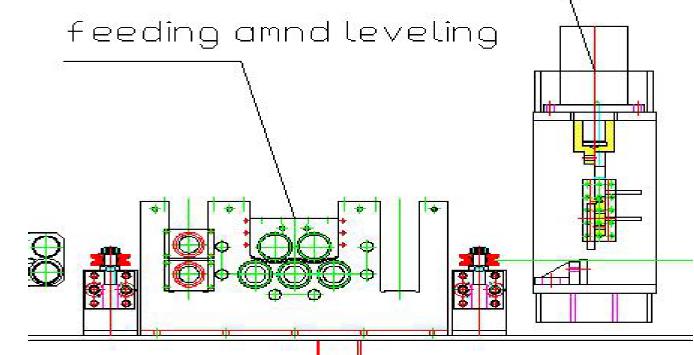

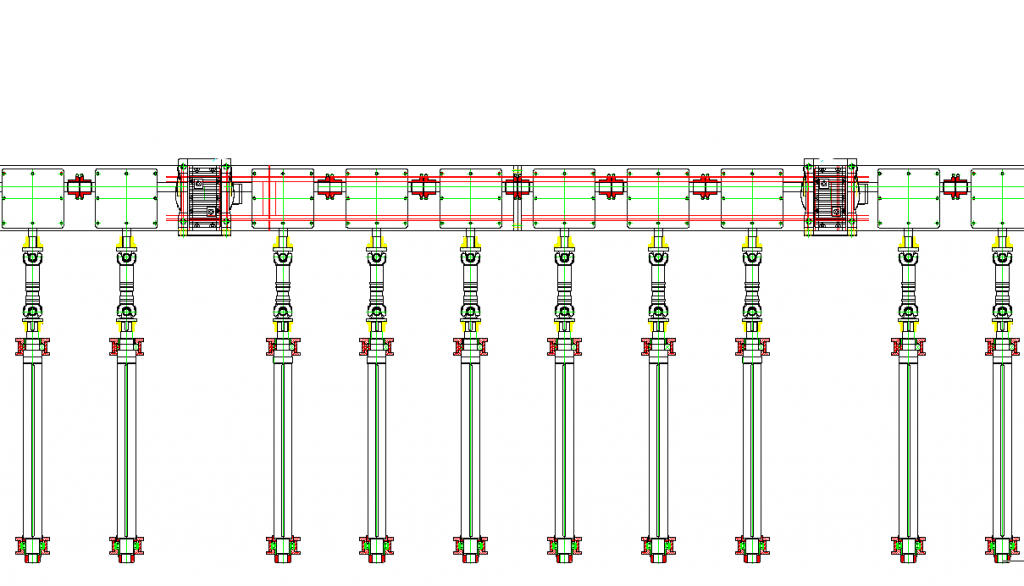

Steel Silo Roll Forming Machine is for producing silo wall panels which is corrugated and curved. Believe Industry have a full range machine for steel silos.

A steel silo is a structure for storaging bulk materials. Steel Silos are used in agriculture to store grain or fermented feed known as silage.

Believe Industry Company have a whole range of roll forming machines for Steel Silo. Such as Grain Steel Silo Corrugated Wall Panel Roll Forming Machine, Steel Silo Post Roll Forming Machine.

Designed for collected the curved corrugated sheets after cutting from the Steel Silo Roll Forming Machine.

In summary, the demand for reliable and cost-effective grain storage solutions makes the steel silo roll forming machine an indispensable asset in modern agriculture and construction. We have explored the precision engineering and automated efficiency these machines bring to the manufacturing process, ensuring high-quality, durable silos ready to withstand the elements. Choosing the right steel silo roll forming machine is crucial for optimizing material usage, reducing labor costs, and achieving the rapid production cycles necessary in today’s global market.

At Beli RollForming, we are committed to being your trusted partner, providing advanced roll forming technology that guarantees both performance and longevity for your silo manufacturing line. Invest in a quality steel silo roll forming machine today to future-proof your storage solutions and secure your competitive advantage. Contact us today to get a free quote.