Address

No 1, Yd Road, Huishan District, Wuxi City, Jiangsu. 214183

Work Hours

Monday to Friday: 9AM - 5PM

Saturday: 9AM - 4PM

C Bracing Section Roll Forming Machine is a specialized industrial line built to transform flat steel coils into high-precision C braces—the unsung heroes of pallet racking systems. Unlike generic roll formers, our machine is optimized for the unique demands of pallet racking manufacturers: it handles thick materials (up to 4mm), produces complex angled profiles, and runs at high speeds to keep up with warehouse storage demands. This is the machine that turns raw steel into stable, safe racking components—fast.

Our C Bracing Roll Forming Machine specializes in one critical product: steel C braces. These angled profiles are the backbone of pallet racking stability—here’s why they matter:

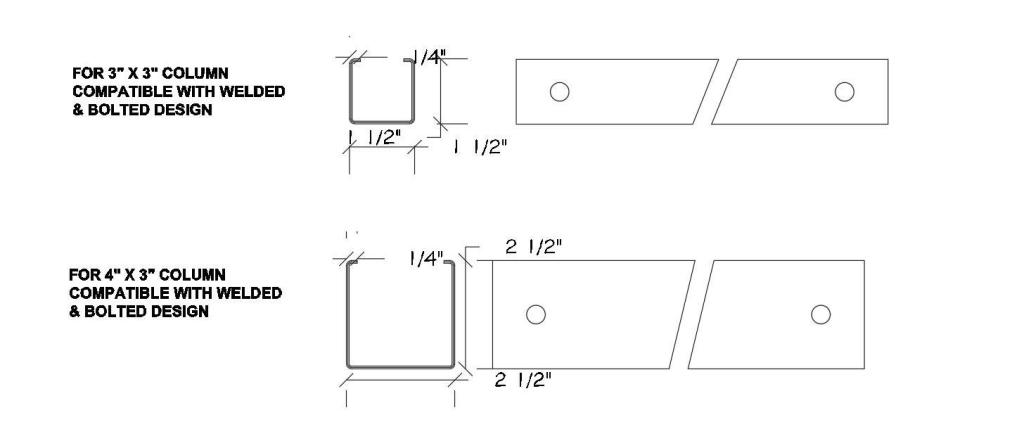

We produce C braces ranging from 40x40mm to 80x80mm (custom sizes available), made from galvanized or cold-rolled steel. Each brace features pre-drilled holes for easy assembly with uprights and beams.

C braces are non-negotiable for safe, durable storage systems:

Load Distribution: They transfer weight from shelves to uprights, preventing sagging and collapse.

OSHA Compliance: Meets safety standards for heavy inventory (pallets, machinery, bulk goods).

Real-world applications: Warehouses, e-commerce fulfillment centers, and manufacturing plants rely on our C braces to keep operations running smoothly.

The complete, automated system ensures seamless, high-speed production of the C-bracing profile. Each component plays a crucial role in the process:

Single Mandrel Uncoiler: Holds the large steel coil and feeds the material into the line.

Feeder and Guider: Ensures the steel strip is accurately positioned and aligned before entering the forming process.

Leveler: Removes coil set, ensuring the material is perfectly flat for high-quality profile forming.

Roll Former: The core of the machine, featuring multiple forming stations that progressively shape the steel into the desired C bracing section.

Straightener: Fine-tunes the profile to ensure the finished product is perfectly straight and meets strict dimensional tolerances.

Tracking Cutoff Unit: A specialized unit that cuts the C bracing to the required length on the fly (while the machine is running), maximizing speed and efficiency.

Collection Table: Receives the finished, cut C-bracing sections, ready for bundling and storage.

Controller Panel (PLC): The centralized control system (often a PLC) used to manage and monitor all machine functions, speed, and length settings.

Hydraulic Station: Provides the necessary hydraulic power for functions such as the tracking cutter and potentially the uncoiler.

For pallet racking manufacturers, the Beli RollForming C Bracing Roll Forming Machine is the key to scaling production without sacrificing quality. With 7 automated modules, customizable specs, and a focus on reducing waste/downtime, this machine delivers the precise C braces your customers need—fast. Whether you’re a small workshop or a large factory, our solution adapts to your needs and helps you stay ahead.

Ready to boost your output? Contact our team for a free, no-obligation quote: Get a Free Quote

For insights into pallet racking industry trends: ProGMA: Pallet Racking Safety Standards