Address

No 1, Yd Road, Huishan District, Wuxi City, Jiangsu. 214183

Work Hours

Monday to Friday: 9AM - 5PM

Saturday: 9AM - 4PM

BELI® also have another roll forming mills, Duplex Mill. which is widely used in Steel Profile Roll Forming Machine. Steel Door Panel Roll Forming Machine, Panel Roll Forming Machine, Sandwich Panel production Line. Cable Tray Roll Forming Machine, C Purlin Roll Forming Machine, U Purlin Roll Forming Machine, C and Z Purlin Roll Forming Machine, etc.

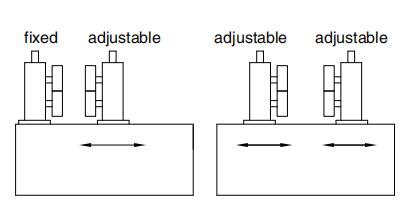

Two cantilevered mills facing each other are called a duplex mill. Duplex mills have one common base and drive . They can form both edges of narrow or wide products leaving the center flat. The minimum strip widths depend on how close the opposing rolls can be pushed together. And the maximum widths usually depend on how far the two mills can be moved from each other. The width of the formed products can be changed quickly by adjusting one or both sides of the duplex mill in or out. BELI® Steel Door Panel Roll Forming Machine is able to form 300-1200 mm width door.

a duplex mill. Duplex mills have one common base and drive . They can form both edges of narrow or wide products leaving the center flat. The minimum strip widths depend on how close the opposing rolls can be pushed together. And the maximum widths usually depend on how far the two mills can be moved from each other. The width of the formed products can be changed quickly by adjusting one or both sides of the duplex mill in or out. BELI® Steel Door Panel Roll Forming Machine is able to form 300-1200 mm width door.

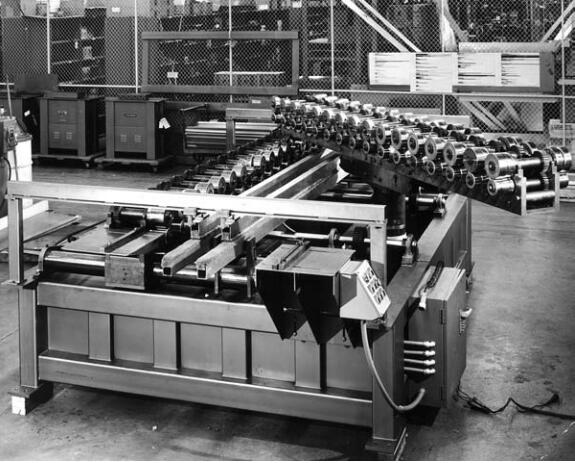

The width adjustment can be manual or motorized. The most sophisticated lines have PLC System to adjust the width, only input the required width on the touch screen, then the machine will be adjusted automatically . Forming rolls installed in a cantilevered or duplex mill are exchangeable to produce different profiles. BELI® offer 2 methods to change the produced profile, one is change the rolls step by step, another one is replace all the mill.( See the right photo) BELI® Steel Door Panel Roll Forming Machine can easy change the profile design, and all are customized. the exchange time will be only 1 hour.

width, only input the required width on the touch screen, then the machine will be adjusted automatically . Forming rolls installed in a cantilevered or duplex mill are exchangeable to produce different profiles. BELI® offer 2 methods to change the produced profile, one is change the rolls step by step, another one is replace all the mill.( See the right photo) BELI® Steel Door Panel Roll Forming Machine can easy change the profile design, and all are customized. the exchange time will be only 1 hour.

Center support is used to avoid buckling of the wide flat center part. Because of the self-weight of the

material, the support is usually placed underneath the center part. However, if the horizontal vector of

the forces is large and the support prevents the sheet to buckle downwards, then it can buckle upwards.

To avoid upward buckling, additional support is placed on the top of the center part. When the width

is changed, the location (and possibly the number of the center supports) has to be changed too. Hence these

adjustments have to be taken into consideration at the design stage. It is also important that the support

should not scratch or mark the product. Embossing, lancing, louvering, or other similar operations, As usual, the door panel width is up to 1200mm or more, so our Steel Door Panel Roll Forming Machine adopt Center Support ” Fluent strip” , easy to adjust.

Subscribe now to keep reading and get access to the full archive.