Address

No 1, Yd Road, Huishan District, Wuxi City, Jiangsu. 214183

Work Hours

Monday to Friday: 9AM - 5PM

Saturday: 9AM - 4PM

Address

No 1, Yd Road, Huishan District, Wuxi City, Jiangsu. 214183

Work Hours

Monday to Friday: 9AM - 5PM

Saturday: 9AM - 4PM

What is Electric Vehicle Battery Tray Roll Forming? Electric Vehicle Battery Tray Roll Forming is a specialized high-speed manufacturing process used to produce structural frames for EV batteries. By progressively bending Ultra-High-Strength Steel (UHSS) or aluminum through tandem roller sets,…

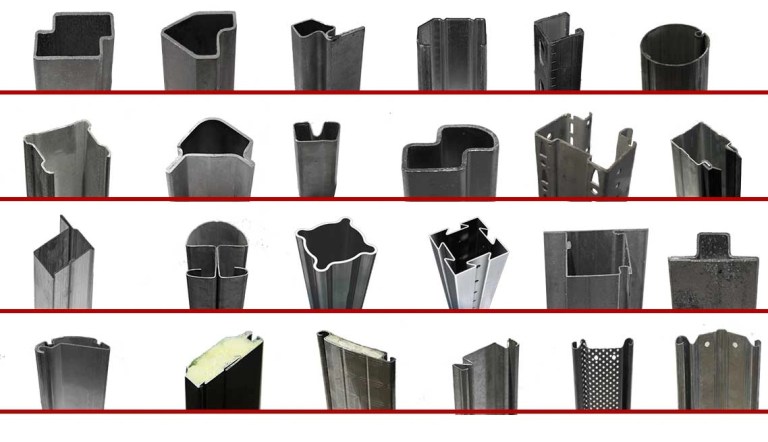

Custom roll formed profiles are complex, continuous metal shapes produced by feeding sheet or strip metal through a series of mated rollers. This process is ideal for long-length, high-volume production, allowing for intricate geometries, integrated punching, and tight tolerances that…

In the competitive landscape of industrial manufacturing, selecting the right metal-shaping process is the difference between a high-margin success and a logistical bottleneck. While both processes create long, consistent profiles, the engineering advantages of roll forming vs extrusion often tilt…

In the high-stakes world of industrial manufacturing, every second of idle time translates to lost revenue. For facilities handling diverse profiles—from rain gutters to complex structural channels—the ability to transition between products rapidly is no longer a luxury; it is…

Master roll forming machine speed optimization with expert tips on material handling, cooling, and tooling to maximize your industrial manufacturing output.

How do you ensure accuracy in solar tracker rail manufacturing? To ensure accuracy, a solar tracker rail roll forming machine must utilize high-stiffness casted stands to prevent machine deflection, integrated servo-driven punching for ±0.5mm hole precision, and a specialized flower…

In the 2026 industrial cycle, the demand for solar infrastructure requires more than just standard equipment; it requires an engineering powerhouse. As a premier global manufacturer, Beli Rollforming delivers the PV mounting structure machine solutions necessary to transform raw galvanized…

What are the primary roll forming machine applications? A roll forming machine application involves the continuous bending of metal coils into precision profiles. In 2026, these applications dominate sectors like modular construction and EV manufacturing, providing ±0.1mm accuracy and high-volume…

How does a solar post roll forming machine ensure structural integrity? A solar post roll forming machine ensures structural integrity by utilizing a series of precision-engineered rollers to cold-form high-strength steel into specific profiles like C, Sigma, or Hat shapes.…

High strength steel roll forming is a specialized cold-bending process that shapes steel with yield strengths often exceeding 550 MPa. Unlike mild steel, HSS requires advanced PLC-controlled overbending, increased roll stands, and high-grade CR12 CNC-machined rollers to compensate for significant…