Address

No 1, Yd Road, Huishan District, Wuxi City, Jiangsu. 214183

Work Hours

Monday to Friday: 9AM - 5PM

Saturday: 9AM - 4PM

Address

No 1, Yd Road, Huishan District, Wuxi City, Jiangsu. 214183

Work Hours

Monday to Friday: 9AM - 5PM

Saturday: 9AM - 4PM

Identifying the Top 10 Roll Forming Machine Manufacturers is essential for construction firms and industrial manufacturers looking to secure long-term production stability. As we enter 2026, the global demand for infrastructure—ranging from solar mounting to modular housing—has transformed the roll…

In the modern construction landscape, the Rain Gutter Machine has evolved from a basic utility tool into a high-precision manufacturing asset. As climate volatility increases the demand for robust water management systems, the ability to produce seamless, high-capacity gutters is…

Knowing how to operate a roll forming machine is the difference between a high-efficiency production line and a series of costly mechanical failures. In 2026, as the industry moves toward high-speed automation and integrated Metal Roll Forming Machine Technology, the…

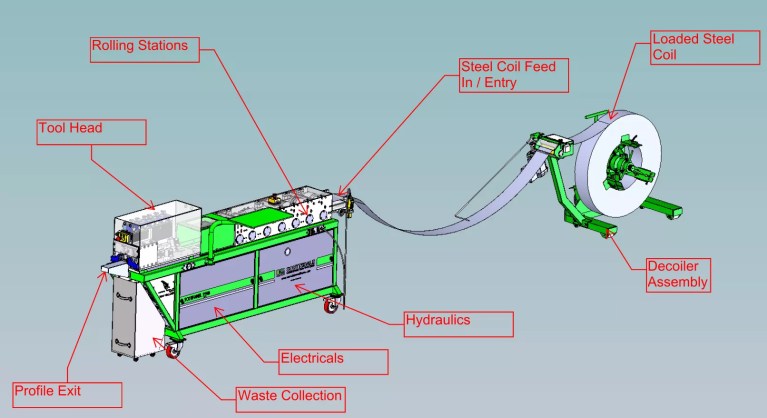

The initial phase of any precision roll forming process is governed by the quality and performance of the Decoiler Machine. This component, which unwinds the metal coil and feeds the material into the forming line, acts as the definitive bottleneck…

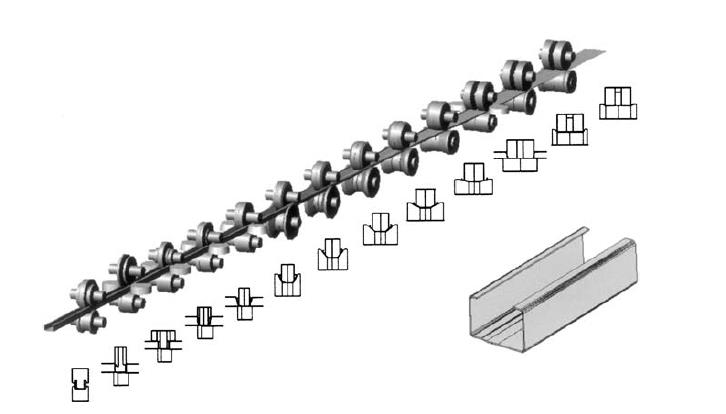

In the realm of metal fabrication, the quality of the finished product is directly contingent upon the performance of the roll forming tooling. These components are not passive; they are the active instruments that determine profile precision, surface integrity, and…

For manufacturers aiming for high volume, superior precision, and minimal material waste, the Roll Forming Process is the undisputed champion. However, maximizing the efficiency and quality of your line requires a thorough understanding of every stage, from the initial coil…

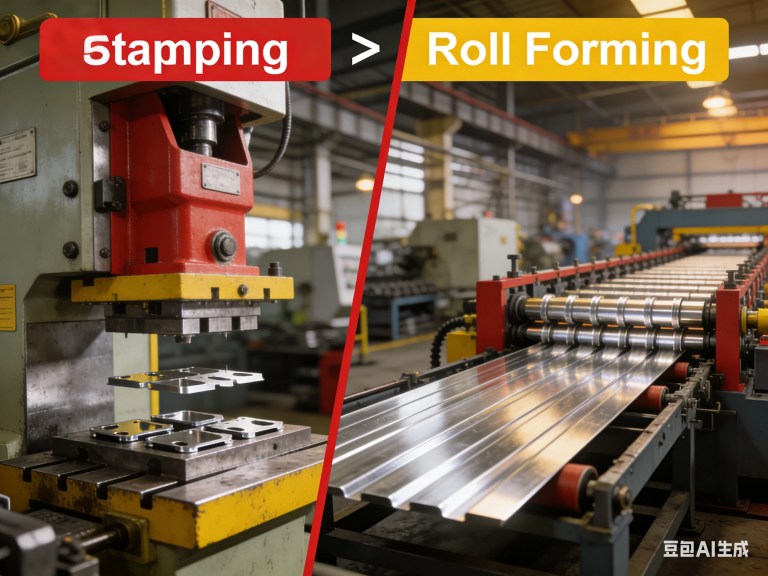

In the competitive landscape of modern manufacturing, selecting the right fabrication process is critical. While stamping, bending, and extrusion each have their place, the continuous, high-volume capabilities of roll forming offer clear and unbeatable advantages of roll forming machine that…

Cold roll forming is a continuous manufacturing process that converts flat strips of metal coil into complex profiles using a series of precisely synchronized roller dies. Unlike other metal forming techniques that rely on heat or immense pressure, this process…

Why Every Roofer Needs This Technology Roll forming machine for roofing systems are revolutionizing construction by transforming raw steel coils into weatherproof, architecturally precise panels in under 90 seconds. Contractors replacing manual methods report: Case Study: After installing Believe Industry’s…