Tile Roll Forming Machine

Tile Roll Forming Machine is a whole automatic line to produce Tiles. The workers only need input the desired data( length, quantity, step length) on the touch screen.

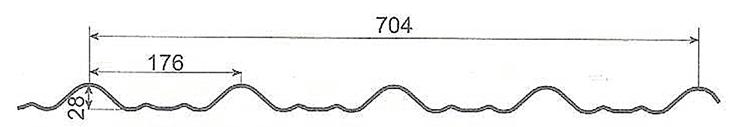

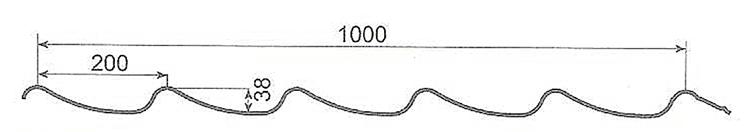

Profile Drawings of Tiles

| 25-200-1000 |  |

| 35-192-960 |  |

| 28-176-704 |  |

| 38-200-1000 |  |

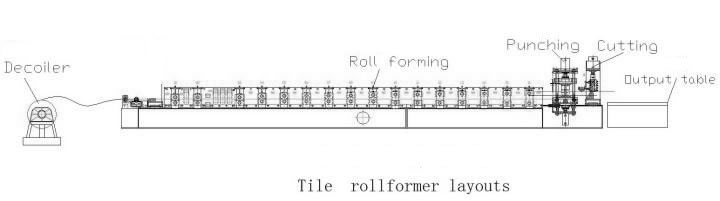

Layout of Tile Roll Forming Machine

The layout of Tile roll forming machine is uncoiling, Roll Forming Machine, Punching Step, Cutting Off, Collecting

Technical Parameters of Tile Roll Forming Machine

5 Ton Hydraulic Uncoiler

- The feeding unit is mechanically separated from the rest of the production line

- Steel coil width:600-1250 mm

- Internal diameter of coil: 480 mm to 560 mm

- Maximal out diameter:1200mm

- Maximum coil weight: 5000 kg;

- Working speed: 0-15m/min adjustable

- Main motor power: 5.5KW AC motor

- Hydraulic power: 4kw

- Speed controlled by frequency converter brand: Yaskawa

Hydraulic expansion and electric uncoiling

Roll Forming Machine

- Structure: Adopt H beam steel and wall panel welded

- Rollers Station: 16 stations

- Diameter of Shaft: 75mm

- Material of Shaft: High quality 45# Steel

- Material of Rollers: 45# Steel, chroming of 0.05mm thickness

- Motor Power: 7.5kw

- Power Transition: Chain and gear

- Speed Control: By frequency converter

- Forming Speed: 3-4m/min (exclude punching and cutting)

- Total weight: About8.5 tons

Tile Roll forming Mill. Quality design and safety

Punch Steps and Cutoff Unit

- The punches will be connected to a single hydraulic unit. This unit consists of tank, motor, pump, pressure control valves, pressure gauges, solenoid valves and hydraulic hoses. All of these are designed to operate safely at the required operating pressure.

- Material of the punches: Cr12,HRC 58-62, chrome coated

- Hydraulic power: 7.5kw

- Working pressure: 12-16 Mpa

- Punching Moulds: 1 group

- Cutting mould: 1 group

- We adopt the cutting device and punching mould in one device.

Punch and Cutting Unit for punch the sheet into tiles and then cut off the tiles into desired length

Hydraulic station

- Hydraulic power: 7.5kw

- Working pressure: 12-16 Mpa adjustable

- Solenoid valve: Beijing Huade

- Hydraulic oil: 46# hydraulic oil

Control System

- The worker input the length and quantity of the product through touch screen, total 20 groups, the touch screen will show the working status of the machine.

- Computer Control System: Panasonic PLC

- Encoder: Omron brand

- Frequency Converter: Yaskawa

- Touch Screen: MCSG

- PLC Brand: Panasonic brand

- Controlled System Power: Overloadprotection

- Voltage: 380V, 50Hz, 3Phase

Believe Industry Company also have roll forming machines for Roofing Sheets, Floor Deck, Downspout, And also custom roll forming machine is designed for special requirements.