Address

No 1, Yd Road, Huishan District, Wuxi City, Jiangsu. 214183

Work Hours

Monday to Friday: 9AM - 5PM

Saturday: 9AM - 4PM

| No. | Description | Unit | Parameters |

| 1 | Yield Strength of the material | MPA | 235-400 |

| 2 | Thickness of the coil | mm | 1.0-2.0 |

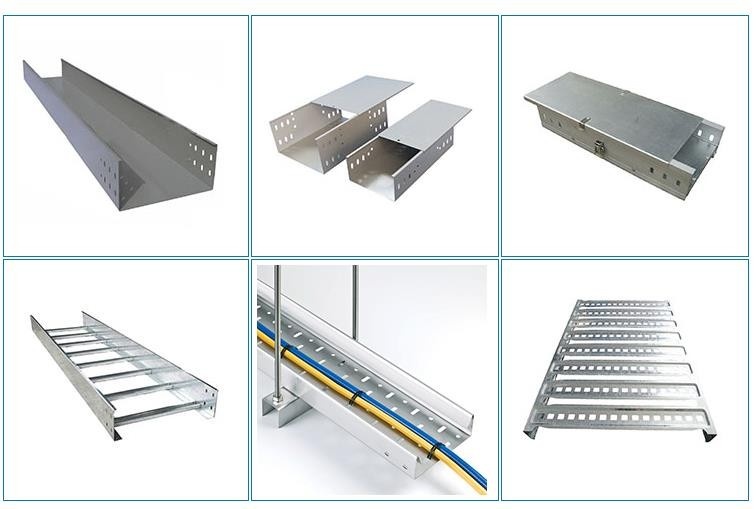

| 3 | Width of the cable trays | mm | 50-600 |

| 4 | Roll forming speed | m/min | 10-15 |

| 5 | Driven Type | Gear Box | |

| 6 | Total Power | KW | 75 |

| 7 | Space Required | m | 55*4*3.5 |

Elevate your production capabilities with Beli Rollforming’s custom-built perforated cable tray production lines—designed for maximum uptime, precise hole punching, and flexible size customization to match your unique manufacturing needs. Partner with us to turn high-demand cable tray orders into seamless, profitable operations—contact Beli Rollforming today to discuss your tailored solution.Elevate your production capabilities with Beli Rollforming’s custom-built perforated cable tray production lines—designed for maximum uptime, precise hole punching, and flexible size customization to match your unique manufacturing needs. Partner with us to turn high-demand cable tray orders into seamless, profitable operations—contact Beli Rollforming today to discuss your tailored solution.