Address

No 1, Yd Road, Huishan District, Wuxi City, Jiangsu. 214183

Work Hours

Monday to Friday: 9AM - 5PM

Saturday: 9AM - 4PM

As we know that, During roll forming, a flat strip is gradually formed to the finished sections, The forming is almost exclusively accomplished groups of rollers while the material go through the roll forming mill. This article will be talking about how roll forming machine design and the process.

Roll Forming Machine design aim is to form the desired sections repeatedly within a specified tolerance. Using the least amount of steps. Or in other word, with the least amount of rollers. “To quick” will distort the product while ” Too slow” will make the machine uneconomical.

View More>> Roller Design Process

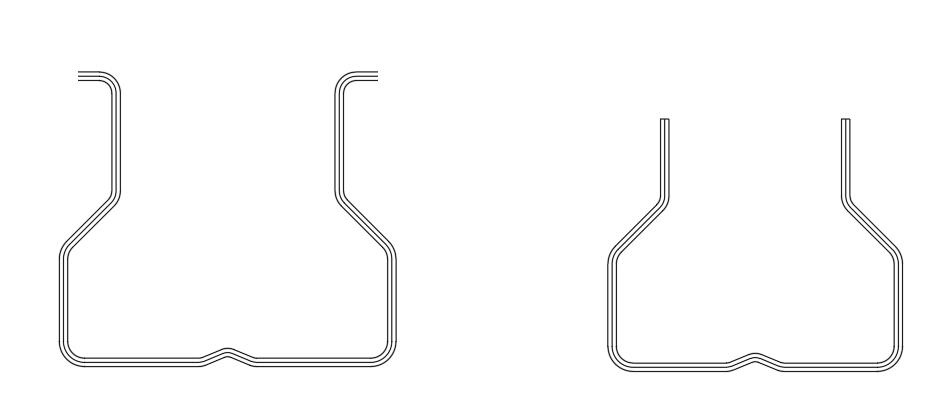

The cross-section of the roll formed product is the most significant factor in roll forming machine design. There are too many different simple or complex sections.

The depth of the section is the maximum vertical dimension of the profile as it exits from the last pass. Which has great influence on the number of rollers.

The width of the flat, nonformed section usually does not influence the number of passes. But the wider the flat (not formed) section and the thinner the material, the higher the chance that waviness will occur.

As usual, relatively shallow grooves are design to improve appearance, minimize center waviness or add strength to the product.And the grooves can be either formed or stretched into the flat area.

Product tolerances will affect the roll forming machine design, the number of passes, and thus the tooling costs.

The designer should ensure that the product can be roll formed with the bending radii before begin the roll forming machine design.

Materials are selected to suit the specified product requirements at the possible lowest price. However, the mechanical properties, surface, deviation from thickness, width, straightness, and flatness of the material will influence roll design.

The roll designer must know the yield strength, maximum tensile

strength, and elongation of the material to design the roll forming machine.

Springback will also affect the roll forming design, which is influenced by the yield stength of the material.

Flare is change of the ends of a roll formed product. And it usually flare out at both ends of deep or high strength material products.

The material must be able to pass through the gap between the rolls without thickness reduction. Therefore, roll gap is calculated as the sum of the maximum specified thickness plus maximum.

Width tolerance will obviously influence some dimensions of the product. And in the end, it will affect the roll forming machine design. And In most cases, the strip width tolerance will be added to the roll forming tolerance at the outside lip.

During roll forming machine design, it is assumed that the imcoming material does not have cable, bow and twist.

Rolls are designed to form the material and they must match the roll forming mill. And the roll designer must have all the relevant equipment dimensions and other data which can influence roll forming design.

The designer should take the maximum thickness, strength, and width of the material in consideration to established the shaft diameter. And then to design the roll forming machine.

Horizontal distance is the dimension from the shaft center to shaft center in the horizontal direction.

The vertical distance is the maximum distance between the center of

the top and bottom shafts. The vertical distance is usually adjustable by manual or by servo motor.

In most mills, the bottom shaft is in a fixed position and is not adjustable. The distance between the center of the shaft and the mill base constrains the maximum bottom roll diameter.

Top shaft drive will add friction, easy to pull and push the coils in the roll forming mill. But expensive and not must have.

Bottom Shaft drive is standard and normally used.

It is obvious that bigger motor will enlarge roll forming speed.

If the users’ factory space is limited and want to change the rollers every 2-6 month. The designer should design and make the roll forming machine interchangeable.

Rollers are split into smaller lengths is for several reasons:

Rollers are always designed to suit specific products within given conditions. But in some conditions the same rolls can be for multiple profiles.

In addition to the conventional forming rolls mounted on parallel, horizontal shafts, side rollers are frequently used for many forming operation. Side-rolls do the same work as the main rolls. Side-rolls are extensively and successfully used in tube forming and should be more widely used in roll forming machine.

The roll designer has to determine the pitch diameter of both top and bottom rolls, as well as calculate the minimum and maximum roll diameters.

The spacers and shims are part of the roll forming machine. At each shaft, the total lengths of the rollers, spacers and shims are equal to the roller space.

One of the most frequently asked question in the roll forming industry is the number of passes required to form a section.

What affect the number of stands?

As technology improved, many designers prefer to use Copra, etc design software as a tool to design the roll forming machines. Which will save many time and labor cost.

Believe Industry Company have an experienced team to design the machines. And the designs catch up to the latest techonology in the world.

Subscribe now to keep reading and get access to the full archive.