Address

No 1, Yd Road, Huishan District, Wuxi City, Jiangsu. 214183

Work Hours

Monday to Friday: 9AM - 5PM

Saturday: 9AM - 4PM

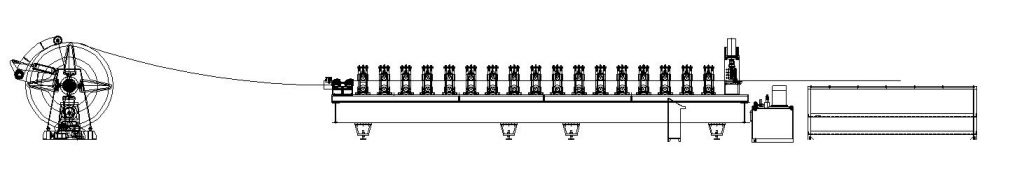

Corrugated Roof Sheet Roll Forming Machine is for producing various width of Corrugated Roof Sheets as desired length and width without any adjustment.

Check corrugated sheet roll forming machine for more information.

Believe Industry Company is engaged in designing and manufacturing Roll Forming Machines, Coil Process Equipments for 10 years. More info about: Mill Base, Roll Forming Stand, Roll Forming Transmission for easy to know the roll forming machine working.

| Weight | 85000 kg |

|---|---|

| Dimensions | 9500 × 1500 × 1500 mm |