Address

No 1, Yd Road, Huishan District, Wuxi City, Jiangsu. 214183

Work Hours

Monday to Friday: 9AM - 5PM

Saturday: 9AM - 4PM

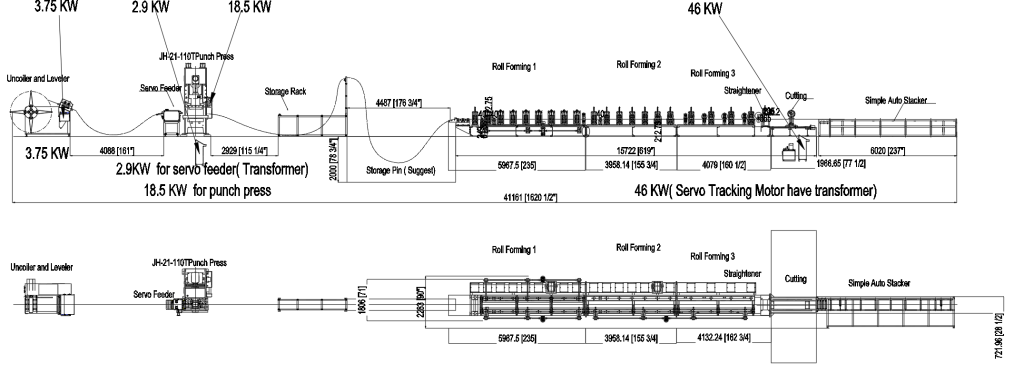

Upright rack roll forming machine technology is the backbone of modern warehouse logistics. At Beli RollForming, we specialize in manufacturing high-precision machinery designed to produce durable upright racks for warehouse pallet rack systems. Our machines are engineered to handle various sizes and thicknesses, ensuring your production line is both adjustable and fully customized to meet global industrial standards.

An upright rack roll forming machine is essential for creating the vertical framework of storage systems. These components, often called uprights or upright columns, vary significantly in size and design based on specific load capacities.

Depending on your client’s needs, the design styles usually fall into three categories:

L-Shape Profiles: Ideal for light-capacity storage.

C-Shape Profiles: The industry standard for medium-capacity shelving.

Special C-Type/Omega Profiles: Engineered for heavy-duty capacity and maximum structural integrity.

Precision is critical during the manufacturing process. During production, holes (such as the popular Tear Drop Design) and slots are punched with extreme accuracy. This ensures that load beams can be mounted securely into the upright racks without alignment issues. For heavy-duty applications, our machines can process material thicknesses up to 3.5mm with ease.

As a leading manufacturer in China, Beli RollForming (also known in the industry as Believe Industry Company) offers diverse machine configurations. Choosing the right upright rack roll forming machine depends on your desired output and budget.

Efficiency is a key metric for any factory. We offer three tiers of production velocity:

High-Speed Lines: Reaching up to 30m/min, perfect for high-volume industrial suppliers.

Medium-Speed Lines: Operating at 10-20m/min, balancing cost and output.

Entry-Level Lines: Reliable production at 3-5m/min for smaller operations.

Modern warehouses require flexibility. Our upright rack roll forming machine solutions feature two adjustment modes:

Automatic Adjustment: Utilizing PLC-controlled systems, the changeover time for different sizes is reduced to just 5-10 minutes.

Manual Adjustment: A cost-effective traditional method where changeover typically takes 2 hours or more.

We understand that every business has unique financial goals. Whether you need a fully automated “Industry 4.0” ready line or a rugged, economic solution to get your business started, Beli RollForming delivers high-quality Chinese engineering to the global market.