C Z Purlin Roll Forming Machine is for producing C and Z Purlins with less change over time. BELI® new technology design, exchange time is only 2 minutes. Our latest design c and z purlin machine price is only around 35000$ EXW factory. Contact us for more inforamtion.

Believe Industry Company have below machines for different requirements of purlins

All abover machines have various design for specific demands.

C Z Purlin Roll Forming Machine

What’s C and Z Purlin?

In steel construction, the term purlin commonly refers to roof structure members that span parallel to the building ridge , and support the roof sheets, wall panels .. The purlins are in turn supported by beams or walls. Purlins are most commonly used in Steel Building Systems, where C -Shapes or Z-shapes are used in a manner that allows flexural continuity between spans. BELI® C Z Purlin Roll forming Machine can form different sizes of C-shape U-shape, Z-shape purlins.

The Measurements of C&Z Purlin

How to change the machine to produce different sizes of C or Z purlin?

Channel or Purlin sections, with or without flange, are usually referenced as C shapes; Channel sections without flange stiffeners are also referenced as U shapes; Point symmetric sections that are shaped similar to the letter C are referenced as C shapes. Section designations can be customized and even specific to a manufacturer. In steel building construction industry, secondary members such as purlins (roof) and girts (wall) are frequently cold-formed steel C, Z or U sections,

C Z Purlin Roll Forming Machine always adopt duplex roll forming mills. It is very easy to change the dimension of the product; for example, the web height (“H”) or the leg length (“L”) of “C” Purlins. If both dimensions have to be changed web height and leg length, marked “H” and “L” respectively then two independently adjustable duplex mills can be combined, using a common drive. Changing the width in the first mill will change the leg length “L”, and changing the second mill will change the web height “H”. BELI® C Z Purlin Roll Forming Machine can form 80-350 mm width C and Z Shape Purlins. and thickness can be up to 5mm.

The two mills have one common centerline. The third dimension, the lip width , can also be changed by adjusting the strip width that enters into the first mill. Or by having a third duplex mill incorporated into the unit . Our C and Z Purlin Roll Forming Machine can produce both C and U Purlin without any change of the rollers. The entry guides and the straighteners are attached to the mill stands. Therefore changing the product dimensions is very simple and quick. Some of these mills are equipped with servo motors and PLC controllers or computers.

Punching holes device on C&Z Purlin Machine

The whole line is containing prepunching or post punch and cutting presses can produce infinite kinds of “C” channels (studs) and “U” channels (tracks) within the parameter of the machine without tool change. Frequently, the only requirement is to enter the part number (or dimensions)and the required quantities into the PLC or Computer system by Touch Screen . The product dimension changeover time can be as low as 1 to 2 min.

How to adjust C Z Purlin Roll Forming Machine

Another quick-change “C” and “Z” purlin mill is forming one edge of the product up. At the other edge no need adjust, the top and bottom rolls can be easily exchanged by either rotating each stand 180º around a shaft or deflecting one leg up for the C Purlin or down for the Z Purlin . These designs enable the production of “C” and “Z” Purlins on the same machine without tool change.

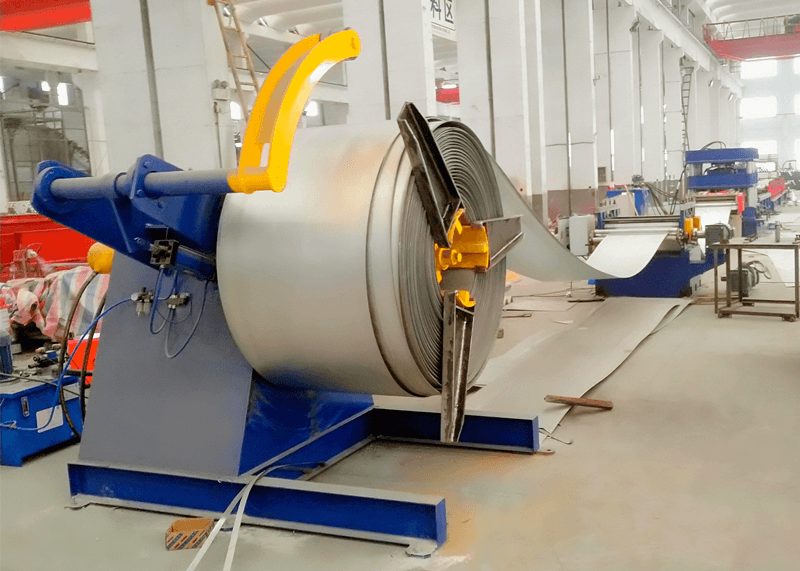

Layout of c and z purlin roll forming machine

The layout of c and z purlin machine is: Uncoiling– Feeding and Guiding– Leveling– Roll Forming– Straightening– Punching Holes– Cutting– Collecting

Technical Parameters of C&Z Purlin Roll Forming Machine

5 Ton Hydraulic Uncoiler

| Description | Specification |

| Type | Electric Uncoiling, Hydraulic Expanding |

| Capacity | 50Ton |

| Maximum Coil Width | 600mm |

| Coil Inner Diameter | 480-620mm |

| Coil Outter Diameter | Max 1600mm |

| Uncoiling Motor Power | 5.5KW |

| Hydraulic Motor Power: | 3KW |

| Uncoiling Speed | 15m/min, will match the speed of the roll forming machine |

Feeding, Guiding and Leveling Device

| Description | Specification |

| Feeding Width Range | 150-600mm |

| Pinch Roller Material | ASTM 1045, chromed surface |

| Side Wall Panel and Wheels | Black Coating |

| Laverling Rollers | Upper 3, Bottom 4 |

| Leveling Rollers Material | ASTM 1045, Chromed, 90mm diameter |

| Leveling Motor Power: | 5.5KW |

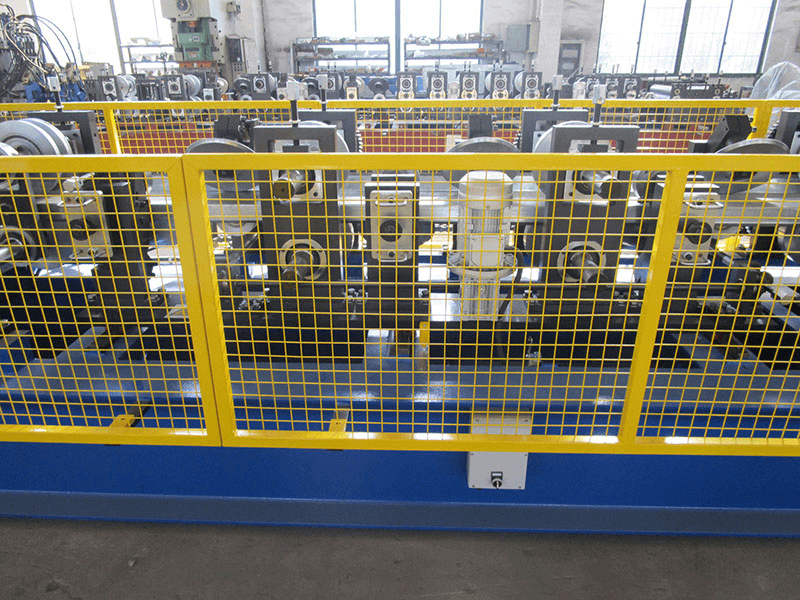

Roll Forming Part

| Description | Specification |

| Machine Structure | H beam welded as base, Iron Cast as roll forming stand |

| Suitable Material Thickness | 1.5-5.0mm |

| Roller Stations | 18 |

| Shaft Material | ASTM 1045, 90mm diameter, HRC 58-62 ° |

| Roller Material | CR12 Mov, HRC 58-62 ° Chromed Surface |

| Driven Motor Power | 37KW |

| Adjust Power | 0.75KW*2 for flange adjust, 1.5KW for web dijust |

| Driven Types | Gear Box |

| Roll Forming Speed | 15m/min |

Punch Holes Device

| Description | Specification |

| Structure | Gantry type, easy to adjust the holes position and replace di |

| Punch Mould Material | CR12, HRC 58-62 ° |

| Hydraulic Motor Power | 7.5KW |

| Hydraulic Working Pressure | 12-16 Mpa |

Multifunctional Hydraulic Cutting Device

| Description | Specification |

| Design | Multifunctional cutting method, easy to adjust the dies, no need to replace the shearing die for different c or z purlins. |

| Cutting Mould Material | CR12, HRC 60-62 ° |

| Hydraulic Motor Power | 7.5KW |

| Hydraulic Working Pressure | 12-16 Mpa |

Controlled Box

| Description | Specification |

| Function | The workers can set the desired data on the touch screen, then the c and z purlin machine will produce the c or z purlin automatically. And also can set different size of c and z purlins on the touch screen |

| Voltage | 380V, 50 HZ, 3 Phase |

| Touch Screen | MCGS |

| PLC | Panasonic |

| Encoder | Omron |

| Inverter | Yaskawa |

| Additional | Aviation plug for easy connecting the wiring |

Believe Industry Company is engaged in design different designs of c and z purlin machines for many years. Contact us for more information. We also have C Purlin Machine, Z Purlin Machine for lower budget.