Klip-Lok Roof Sheet Roll Forming Machine

What’s Klip-Lok Roof Sheet?

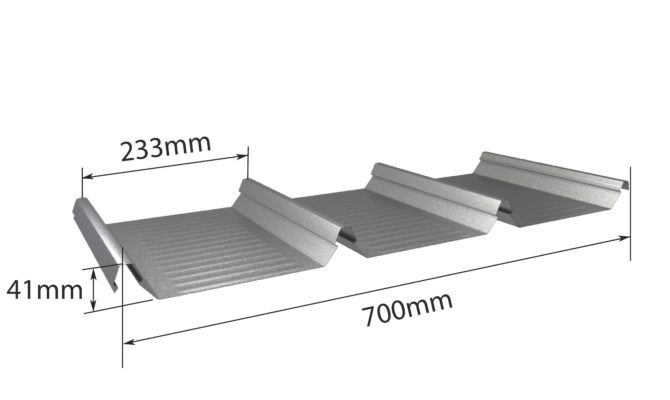

Klip-lok roof sheet is a wide-cover concealed fixed cladding with no exposed fasteners for weathertight roofs. Visually, a bold rib makes a strong statement rising from the flat pans. Thermal expansion of long, straight runs are acheivable, and with no exposed fasteners, the long, straight lines remain clean and smooth.

Types of Klip-lok Roof Sheets

The profile shall have 3 or 4 trapezoidal ribs at 233mm centres giving a nett cover of 406 or 700mm. The male rib shall have spurs to ensure a positive double interlocking action at side-laps. Each pan shall incorporate two stiffener ribs.

The roof sheeting shall be double-interlocking concealed-fix Klip-Lok profile roll-formed in continuous lengths and cut to length by a pneumatic cut-off process from Galvanised steel 0.4-0.6mm.

Klip-Lok Machine Components

- Uncoiler, Manual or Automatic

- Feeder and Guider

- Roll Forming Mill, Rollers,Shafts

- Cutoff Unit

- Hydraulic Station

- Controlled Panel

- Collection Table

Brief Introduction of Klip-lok Roll Former

- Uncoiler Capacity: 5 Ton

- I.D of the coil: 500-650 mm

- O.D of the coil: Max 1500 mm

- Thickness of the coil : 0.4-0.6 mm

- Coil Width : 940 mm or 610 mm

- Forming Steps: 32

- Main Motor Power: 15 KW

- Roller Material: ASTM 1045, quenched and chromed 0.05 mm thickness

- Shaft Material: Solid, 75 mm, ASTM 1045.

- Driven Method: By Chain and Gear

- Control system with intelligent PLC and HMI touch-screen helps to operate machine simply and to create identical klip-lok roof sheets which present your exact specifications.

Believe Industry Company have a full range of Roll Forming Machines for building materials. Such as;