Address

No 1, Yd Road, Huishan District, Wuxi City, Jiangsu. 214183

Work Hours

Monday to Friday: 9AM - 5PM

Saturday: 9AM - 4PM

Address

No 1, Yd Road, Huishan District, Wuxi City, Jiangsu. 214183

Work Hours

Monday to Friday: 9AM - 5PM

Saturday: 9AM - 4PM

Roll Forming Machine, to forming steel coils/strips along straight, longitudinal, parallel bend lines with multiple pairs of contoured rollers without changing the thickness of the material at room temperature. Believe Industry Company have a full range of roll forming machines for Roofing Sheets, Wall Cladding, Steel Floor Decks, Studs and Tracks, purlins And also for Warehouse Storage System, Roller Shutter Door System, Garage Door System, etc.

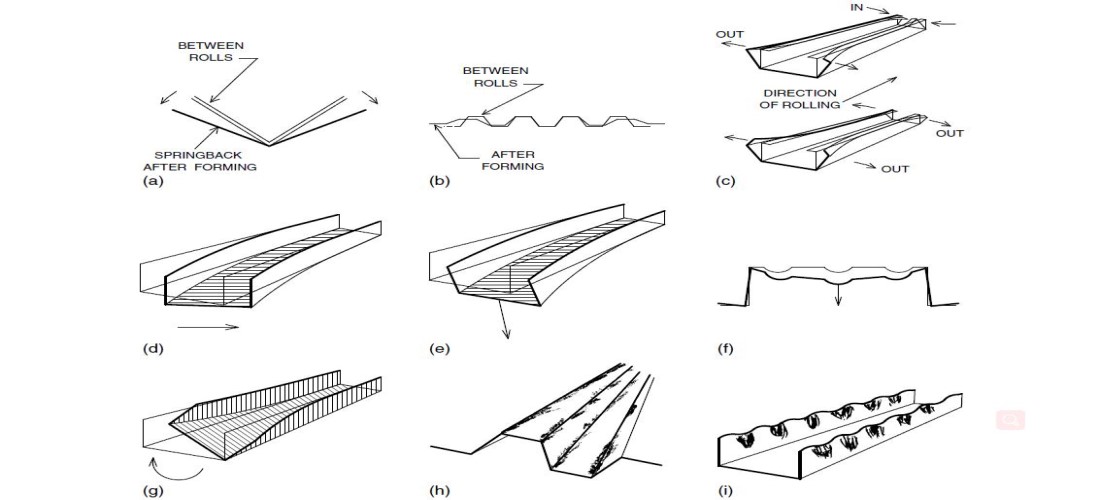

Roll Forming machine is a flexible process, where both the dundamental rules and the exceptions can be utilized. It have been proben several times that even seemingly impossible roll forming tasks can be accomplished, although it may take a longer time and much more money. On the other hand, it has also been shown that plans to roll form simple shapes can create disastrous results if the basic rules of roll forming are not followed..

From our website, you will learn how to choose a suitable roll forming machine as well.

Metal Floor Deck Machine is for producing metal floor decking as per drawings. The thickness is 0.8-1.5mm as usual.

Purlin Roll Forming Machine is for produce purlins as the desired measurements and length. Purlin Roll Forming Machine Purlins Classification. In steel construction, the term purlin typically refers to roof framing members that span parallel to the building eave, and support the…

Last week, Believe Industry Company have shipped a metal glazed tile roll forming machine and roofing sheet roll forming machine to Canada. The 2 machines have been loaded in one container to save the freight cost. 45 days ago. The…

Roll forming machine troubleshooting is one of the basis skills of an operator. This article will show the reader some common problems and solutions about length tolerance

Different customers have different roll forming machine requirements. Here will talking about the basic requirements Roll Forming Machine Requirements Satisfying Customers Roll formed products are sold to customers in a very competitive market. Customers are always looking for manufacturers who will repeatedly meet with their basic necessities. they’re expecting to receive: The proper quality…

Questions To Ask Before Buy Roll Forming Machines The Companies buy roll forming machines on who have the best quality and the lowest price. But the most important thing is the roll forming machines can meet their requirements. So before…

Roll Forming Machine Design Complexity of profile drawings The profile drawings of the roll formed profiles is the most signficant factor in roll forming machine roller design. There variety of shapes is not limited. And the shapes can be arbitrarily…

CNC Roll Forming Machine is for producing the desired steel products. How to choose the best cutting solution?

From this post, you will know what the troubles of operating the roll former machine you will meet, and how to preventing the troubles.

As a China Roll Forming Machine Supplier, Believe Industry Company is engaged in designing and manufacturing series kinds of roll forming machines as per requirements.