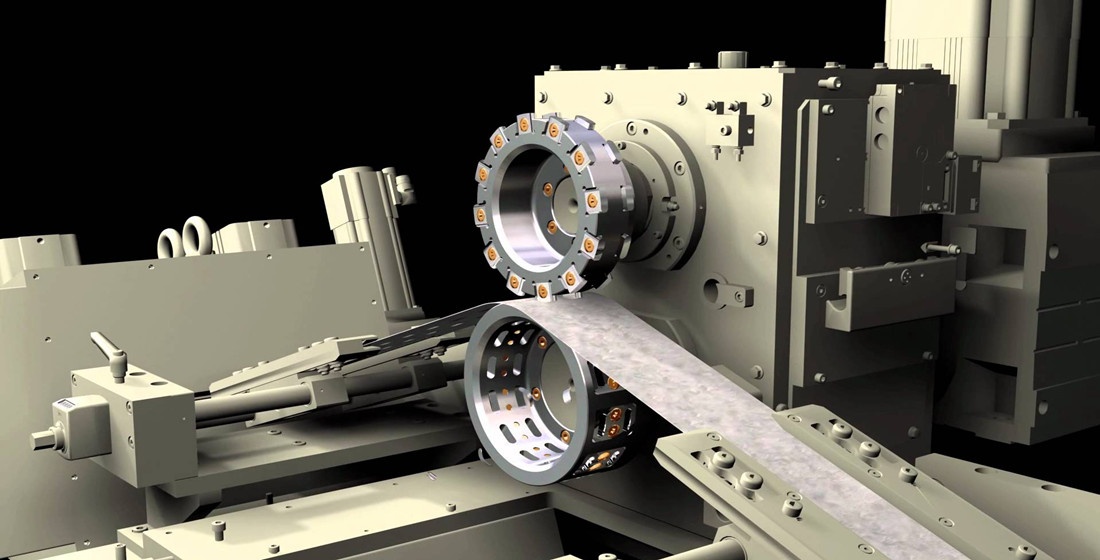

A Metal Embossing Machine Line is a metal forming process unit that emboss a series of straight or parallel ridges onto a metal sheet or strip.

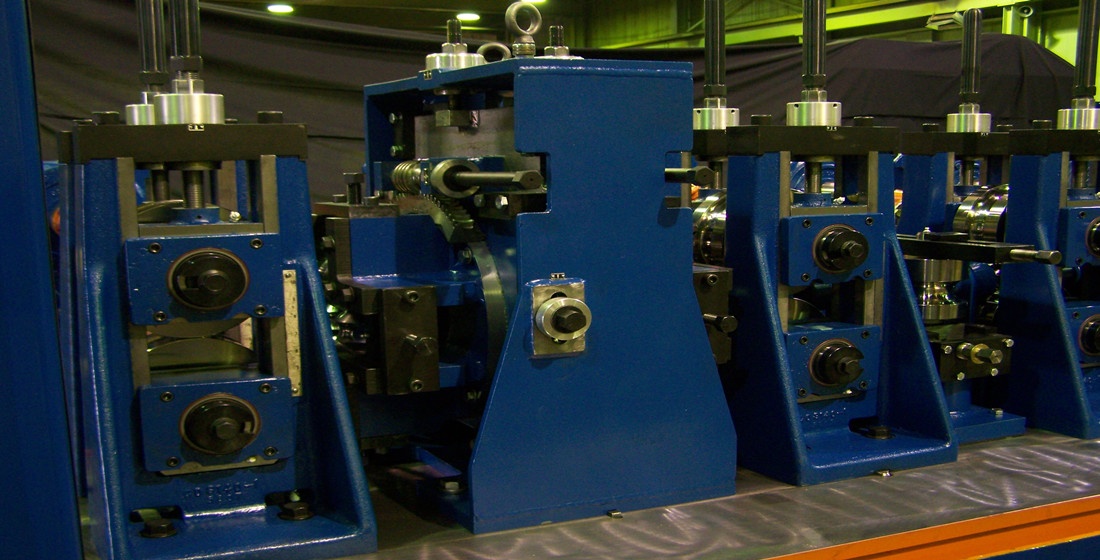

Roll Forming Machine Part-Spacers and Shims

Spacers and Shims are part of Roll Forming Mills( Roll Forming Machine Part). The total length of the rollers, shims, spaces are equal to the length of the roller space(inner width of the roll forming stand)