Address

No 1, Yd Road, Huishan District, Wuxi City, Jiangsu. 214183

Work Hours

Monday to Friday: 9AM - 5PM

Saturday: 9AM - 4PM

Address

No 1, Yd Road, Huishan District, Wuxi City, Jiangsu. 214183

Work Hours

Monday to Friday: 9AM - 5PM

Saturday: 9AM - 4PM

Cold Roll Former Cutting Position As we know that, a continuous cold roll former( cold roll forming machine) is a whole line with the cutoff die. The Coil strips move continuously during the roll forming production. Only if you use…

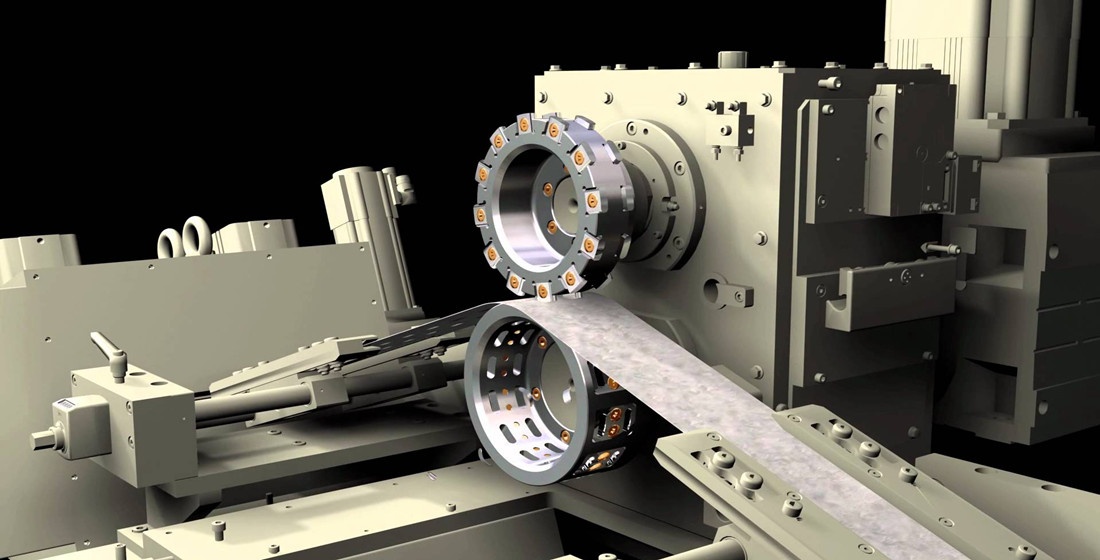

Rotary Punch In the Roll Forming Industry, there a new unique rotating dies for punching, notching, partial punching, dimpling, embossing which is named Rotary Punch.

To eliminate the deformation by the internal stress which is created by the roll forming press. A straightener is generated. Usually, wide building sheets remain straight after roll forming. but most narrow steel profiles and especially asymmetrically roll formed steel profile will required a straightener.

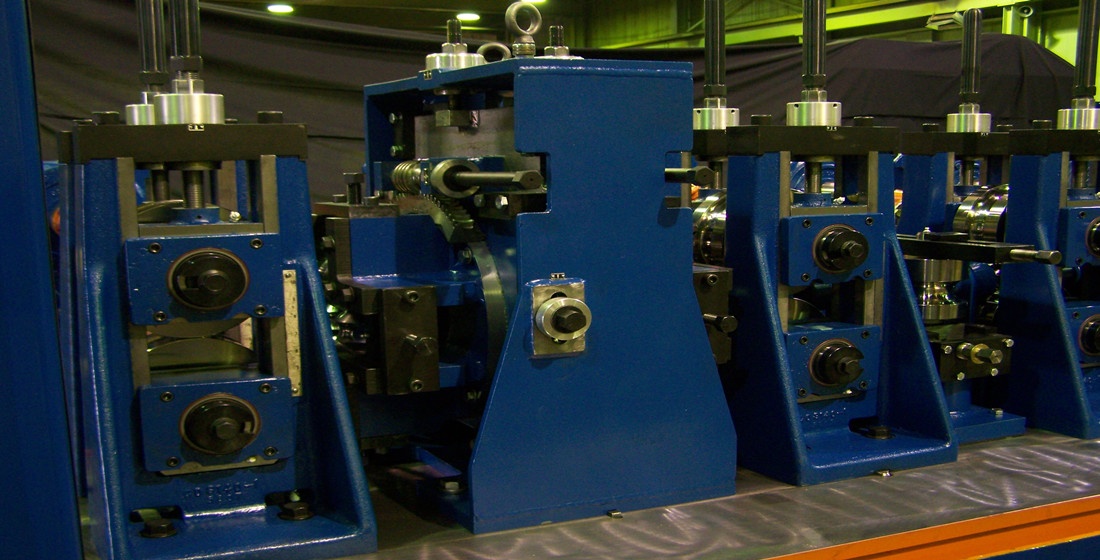

Steel Roll Forming Machine Line, to forming steel coils/strips along straight, longitudinal, parallel bend lines with multiple pairs of contoured rollers without changing the thickness of the material at room temperature.

Roll Forming machine is a flexible and continuous process, where both the normal rules and the exceptions utilized. It have been proven several times that the roll forming machine accomplish roll forming tasks which even seemingly impossible. Although it may take a longer time and much more money. On the other hand, it also showed that plans to roll form simple shapes can create disastrous results. If the designer don't follow the basic rules of roll forming.

Roll Forming Mill Side Roll The History of Side Rolls In the early applications, Roll Forming Machine is based on the mail roll forming rollers. And if the output product is unsatisfied, then the designer will add some side roll…

Roll Forming Transmission are usually powered by electric motors. In only few cases, roll forming mill are driven by hydraulic motor. Most hydraulic motors powered by hydraulic station by electric motors. And at some remote job site, the truck-mounted (Portable) roll forming machine is driven by diesel engine.

In most cases, the drive-side stands are exposed to considerable forces and bending moments. The operator-side (outboard) stands are exposed to lesser forces. They usually support the shafts through bearings and bearing blocks. As a result, there are no forces acting on the roll forming stand in the axial direction of the shaft. The vertical forces are contained by the vertical legs of the stands.

Mill Base Most Important Requirements for Mill Base The mill base, sometimes called “ bed ” supports the stands, shafts, rolls, drive train, and the components needed to form the sections. The most important requirements for the base are: Rigidity…

Steel Roll Forming Machine Steel roll forming machine is a continuous process which coils or strips is fed into groups of rollers. While the coils or strips pass through the rollers, it gradually forms a shape with the desired profile.…

Custom Roll Forming Machine Custom Roll Forming Machine adopt advanced on-line pre-punching cold roll forming technology. Witch can reduce the production and processing difficulty of cold roll formed parts with holes. And also reduce the consumption of materials, and ensure…