Address

No 1, Yd Road, Huishan District, Wuxi City, Jiangsu. 214183

Work Hours

Monday to Friday: 9AM - 5PM

Saturday: 9AM - 4PM

Steel Roll Forming Machine Line, to forming steel coils/strips along straight, longitudinal, parallel bend lines with multiple pairs of contoured rollers without changing the thickness of the material at room temperature.

Roll Forming machine, also named “Roll Former“, which is a flexible and continuous process, where both the normal rules and the exceptions utilized. It have been proven several times that the roll forming machine accomplish roll forming tasks which even seemingly impossible. Although it may take a longer time and much more money. On the other hand, it also showed that plans to roll form simple shapes can create disastrous results. If the designer don’t follow the basic rules of roll forming.

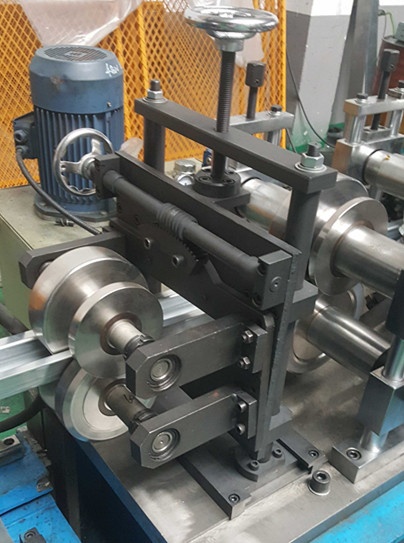

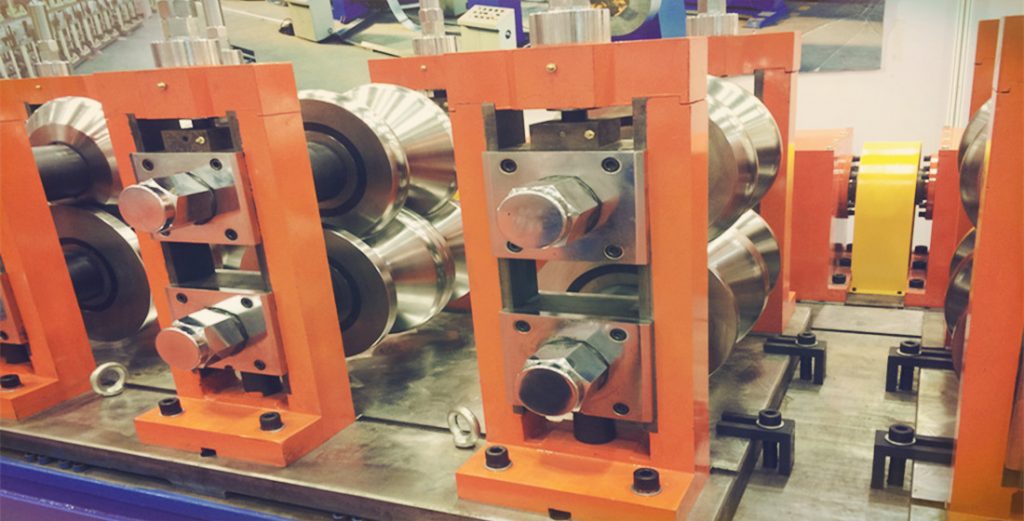

The heart of the roll forming line is the mill. The mill provides the power and support to the tooling that forms the metal. Assemble the compete roll forming line on the shaft shoulders of the roll forming mill. The variations in mill design and mills can be classified as:

Various design of special application mills are in use by the roll forming machine industry. Maybe many of do not fit with the previous mills, but they also work properly.

Roll Forming Machine always require an unit to cutoff the coil strips of products into length. And the position can be ahead of the roll forming mill, between the roll forming stands, or after roll forming mill. Mostly used cutoff method as below:

See more information of different position of cutoff unit.

The straightener is forming the product with a camber or with a bow with enough pressure to create a permanent deformation in the opposite direction of the deviation. If the deformation in the opposite direction is correct, then after springback, the product will be straight

The punching, notching, mitering and other operations have the same press structures. While design the roll forming machine, we would considering the dies design, 2 types:

After punching, removing a part of the material, the removed part is scrap. Punching, Perforating, Notching. And also complete other press operations in loose or tight line.

After embossing and drawing, a part of the coil is stretched out of its original plane without shearing.

Many products(such as doors and shelving) need to bend the ends of the section. In most case, the bend is perpendicular to the longitudinal bends made by roll forming.

Some products( like U Channel, roofing sheets, steel silo, door guider track) need to be curved after cutting into length.

Utilizing the continuous rolling pf the strips propelled by the roll forming mill. The top and bottom rollers are geared together. One roller hold the punch heads, and another roller hold the punch dies.

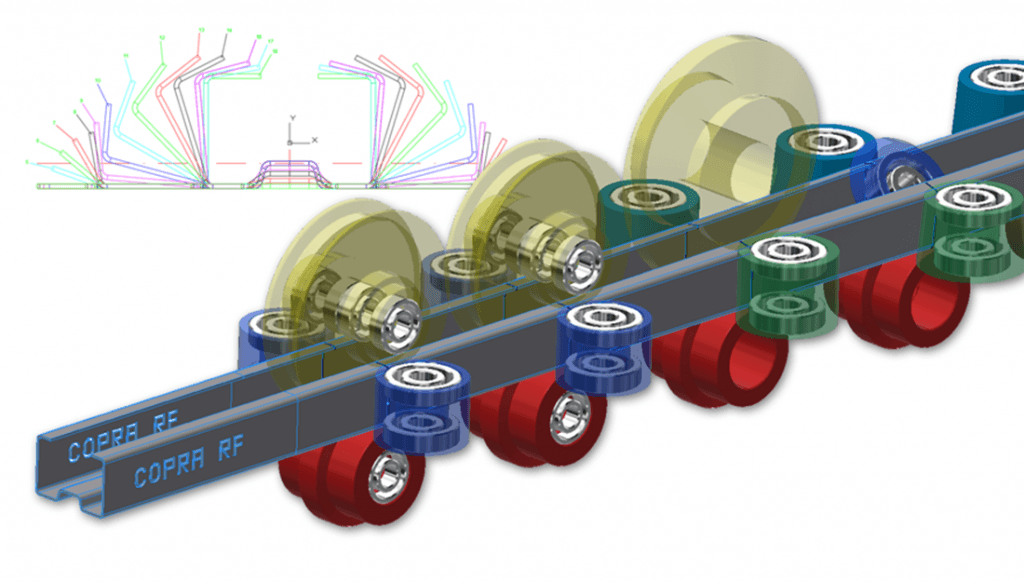

Believe Industry Company adopt Copra RM to design the machines, which is the newest technology for roll forming design. As years’ experience, Believe Industry Company machines are used for all the steel industries. And most of them are customized:

Furthermore Believe Industry’s Roll Forming Machines also for Guardrails, Strut Channels, Cable Trays, Posts, etc applications. In addition Believe Industry Company also supply coil process equipment: slitting line, cut to length line, blanking line for steel factory.

If you are new in roll forming machine, you can answer or collect the information of “Questions To Ask Before Buy Roll Forming Machines” or contact usdirectly. we will teach you how to buy a suitable roll forming machine and how to maintenance the machine.Or read the FAQ for a brief information. If you have bought roll forming machines before. Also contact us. we will let you know a new technology of roll forming machine.

Subscribe now to keep reading and get access to the full archive.